Enameled Wire Electrical Wires Cable 180℃ 1.900mm Bare Copper Conductor Polyester Imide Insulation 5000V Aero Engine Auxiliary

Paglalarawan

Mga pangunahing katangian

| Materyales ng konductor | Bulaklak na bakal | Diyametro | 1.900mm |

| Ang materyal ng insulasyon | Polyester imide paint | Tayahering Kuryente | 5000V |

| Lugar ng Pinagmulan | Jiangxi, China | Model Number | EIW |

| Pangalan ng Tatak | HUAERDA | Paggamit | Mga industriyal na motor at kagamitang elektrikal |

| Conductor type | Solid | Anyo | Bilog |

| Temperatura | 180℃ | TYPE | Naka-insulate |

Pagbabalot at paghahatid

| Yunit na ibinebenta | kilogramo |

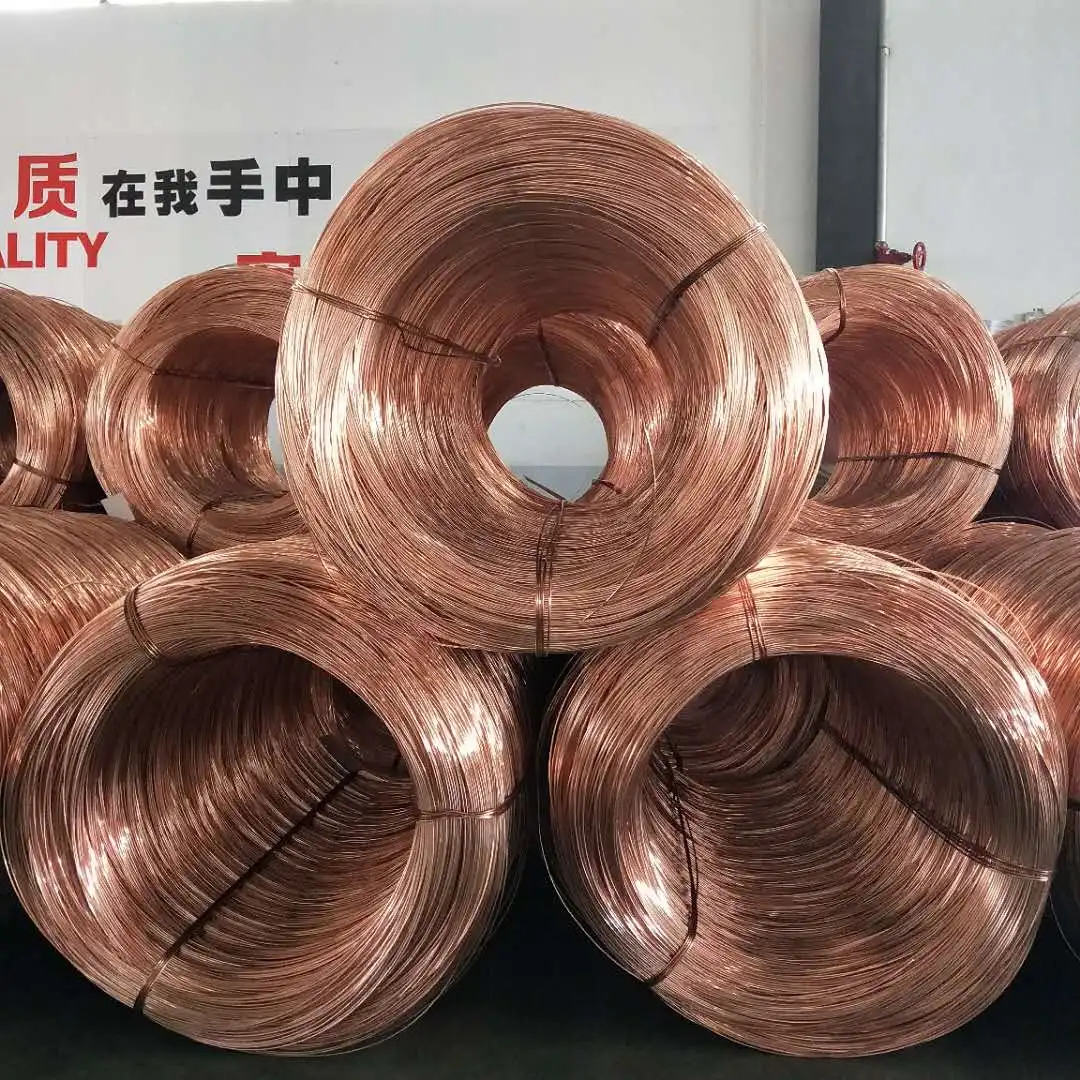

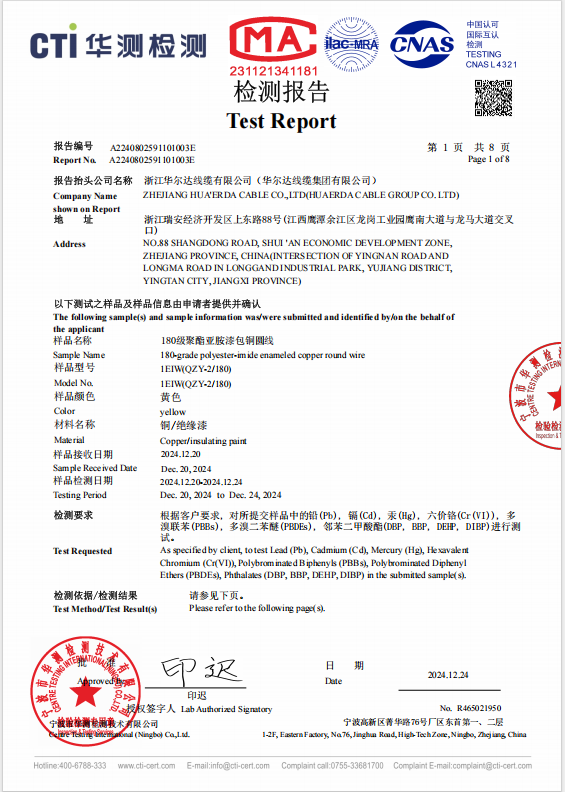

Ang HUAERDA Enameled Wire Electrical Wire Cable ay isang de-kalidad na produkto na idinisenyo upang matugunan ang mahigpit na pangangailangan sa elektrikal at industriya. Binubuo ang wire ng bare copper conductor na may sukat na 1.900mm, na nagbibigay ng mahusay na conductivity at tibay. Pinapalitan ang tanso ng makinis na patong ng enamel insulation na gawa sa polyester imide, na kayang tumagal sa mataas na temperatura hanggang 180°C. Dahil dito, angkop ito para gamitin sa mga kapaligiran kung saan mahalaga ang pagtutol sa init, kabilang ang aerospace applications at iba pang high-performance na industriya

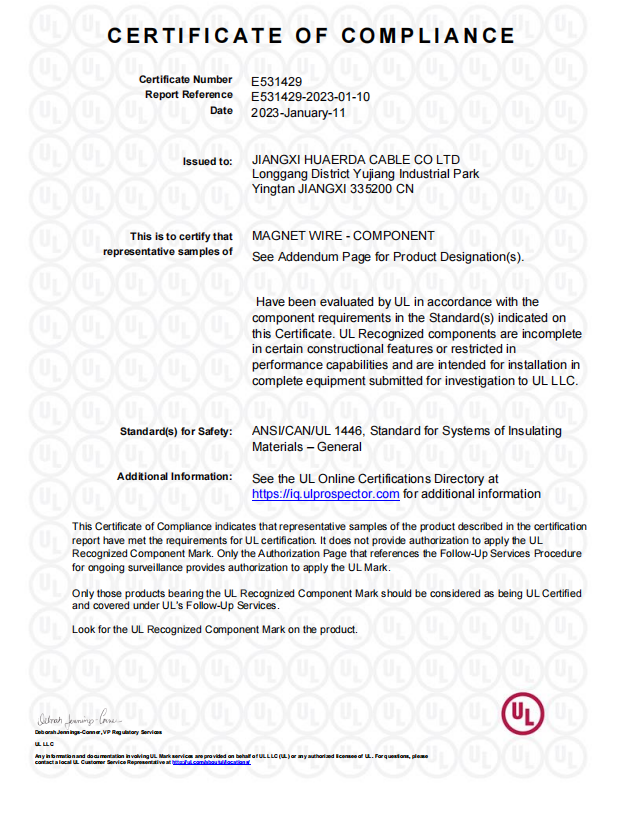

Isa sa mga natatanging katangian ng HUAERDA na enameled wire ay ang kakayahang magproseso ng mataas na boltahe hanggang sa 5000 volts nang ligtas. Dahil dito, ang wire ay isang mainam na pagpipilian para gamitin bilang auxiliary cable sa aero engine, kung saan napakahalaga ng parehong reliability at kaligtasan. Ang polyester imide insulation ay nagbibigay ng matibay na proteksyon laban sa electrical breakdown, mechanical abrasion, at chemical exposure, na tinitiyak ang matagalang pagganap kahit sa mahihirap na kondisyon

Ang disenyo ng wire ay nakatuon hindi lamang sa pagganap kundi pati na rin sa kadalian ng paggamit. Ang kakayahang umayos nito ay nagpapadali sa pagbibilog at pag-route sa masikip na espasyo, na madalas kinakailangan sa mga kumplikadong makina o electronic device. Bukod dito, ang enamel coating ay nagbibigay ng makinis at pare-parehong tapusin, na tumutulong upang maiwasan ang short circuits at mapanatili ang matatag na electrical connection sa paglipas ng panahon

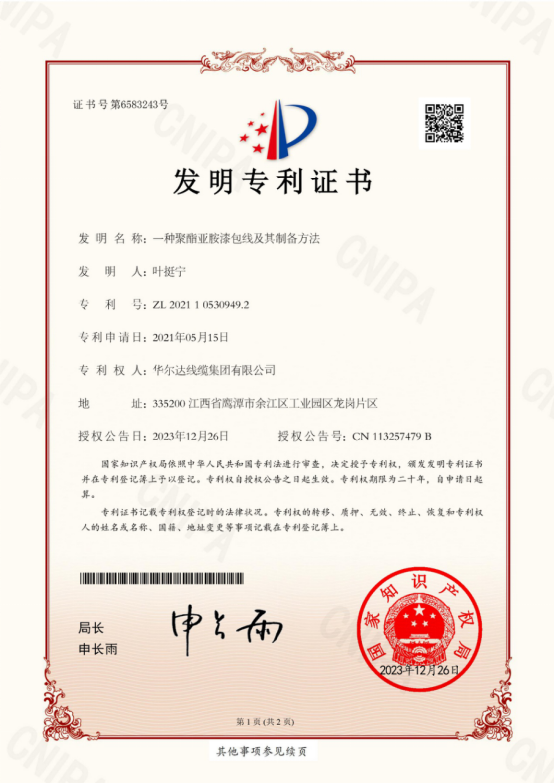

Ang HUAERDA ay isang pinagkakatiwala brand na kilala sa paggawa ng maaing at matibay na electrical components. Ang kanilang enameled wires ay dumaan sa mahigpit na kontrol sa kalidad upang matugunan ang mga internasyonal na pamantayan, tiniyak na ang bawat roll ay nagbibigay ng pare-parehong resulta. Kapag sa pag-ayos ng umiiral na kagamitan o sa pagdidisenyo ng mga bagong electrical system sa larangan ng aviation, automotive, o industrial, kayang tiyak ang wire na ito ang mga pangangailangan na inilagak sa ito

Ang HUAERDA Enameled Wire na may 1.900mm bare copper conductor at polyester imide insulation ay isang mahusayng pagpipilian para sa mataas na temperatura at mataas na boltahe na aplikasyon. Ang mataas na resistensya nito sa init (hanggang 180°C) at ang kakayahon na gumana nang ligtas sa 5000V ay nagpabago ito na lalo na para sa auxiliary na gamit ng aero engine. Ang matibay na istraktura at maaasahang insulation ng wire ay tiniyak na gumana ito nang maayos sa mahirap na kapaligiran, na nagpabago ito ng isang maaasahang komponen para sa inhinyero at teknisyan. Kung kailangan mo ng matibay, heat-resistant, at mataas na boltahe na electrical wire, ang HUAERDA enameled wire ay isang matalinong solusyon

Paalala:

TYPE |

Polyester |

Binago na Polyester |

Ang polyurethane |

Ang polyurethane |

Polyesterimide |

Poliamida-imide |

Kodigo |

PEW, QZ |

PEW, QZ |

UEW, QA |

UEW, QA |

EIW, QZY |

EI/AIW, QZY/XY |

Klase ng Pag-init |

Klase B, 130℃ |

Klase F, 155℃ |

Klase F, 155℃ |

Klase H, 180℃ |

Klase H, 180℃ |

Klase H, 200℃/220℃ |

1. Tanong: Gaano kahusay ang minimum diameter ng enameled wire

A: Ang pinakamaliit na diameter ng enameled wire na ipinaproduhe namin maaaring umabot hanggang 0.060 mm. Gumagamit kami ng intelligent process control upang siguruhin na mahihila pa rin ang mga exelente insulation at high temperature resistance sa demand ng mataas na presisyon, na madalas na ginagamit sa mga larangan ng clicks, elektrikal na aparato, bagong enerhiya ng sasakyan, 5G communication at iba pa.

3. Tanong: Tugma ba ang mga conductor materials sa mataas na pamantayan

Sagot: Ginagamit namin ang annealed low-oxygen at oxygen-free copper wires, na mas mahusay kaysa ordinaryong tanso sa oxidation resistance at conductivity, at nagtagumpay sa industry certification. Halimbawa, ang purity ng conductor ay 99.97%, na nagsisiguro ng mababang resistance at mababang heat generation sa mahabang paggamit

4. Tanong: Ilan ang lead time para sa delivery ng order

A: Para sa stock, maaari naming iship ang mga kalakal sa port ng pagmu-multiply sa loob ng 7 araw ng trabaho pagkatapos naming matanggap ang deposito. Para sa panahon ng produksyon, karaniwang tumatagal ng humigit-kumulang 15 hanggang 30 araw upang iship ang mga kalakal sa port ng pagmu-multiply pagkatapos naming matanggap ang deposito

5. Q: Paano harapin ang mga problema sa kalidad

A: Mangyaring menjan ng produkto at kontakin ang serbisyo sa customer

6. Q: Bakit ako bumibili ng enameled wire na may maraming pinholes sa salt water test

A: Ang pambansang pamantayan ay nagsasaad na ang tamang paraan ng pagkuha ng sample para sa pagsusuri ay hindi dapat mailagay sa tensyon o hindi kinakailangang pagbaluktot ang specimen kapag inaalis ito mula sa pakete. Bago bawat pagsusuri, dapat alisin ang sapat na insulated wire upang matiyak na walang nasirang bahagi ang specimen. Huwag kailanman ipalubog o ibaluktot ang yo

7. Q: Bakit ang resistance na sinusubok ay mas mataas kaysa sa tinukoy na saklaw

A: Ang pambansang pamantayan ay nagtatakda ng 20 ℃ bilang kapaligiran para sa pagsubok ng resistance, ang karaniwang temperatura sa rehiyon ng timog ay nasa mahigit 30 ℃, at ang karaniwang customer ay walang sariling laboratoryo na may kontroladong temperatura, kaya't mataas ang resulta ng pagsubok. O kaya ayon sa index ng temperatura na nakonbert sa resistance sa 20 ℃

9. Q: Habang gumagamit ng fine wire, maraming lilitaw na thread at hindi makita ang mga thread

A: Mahina ang lakas ng pag-stretch ng manipis na sinulid, madaling putulin ang sinulid. Kailangan lamang ipunin nang mano-mano ang lahat ng sinulid (maaaring hindi makita ang sinulid sa ibabaw ng linya), dahan-dahang ipunin ang basurang linya, alisin ang ilang basurang linya, at sa huli ay magiging isang sinulid. Ang paghahanap ng sinulid ay ang pag-alis ng ilang basurang linya, huwag mag-alala, mangolekta nang may kumpiyansa, huwag matakot yo