एनामेल्ड वायर इलेक्ट्रिकल वायर केबल 180℃ 1.900मिमी बेयर कॉपर कंडक्टर पॉलिएस्टर इमाइड इन्सुलेशन 5000वी एयरो इंजन सहायक

विवरण

प्रमुख विशेषताएँ

| चालक सामग्री | नंगा कॉपर | व्यास | 1.900 मिमी |

| बिजली से बचाव का पदार्थ | पॉलिएस्टर आइमाइड पेंट | रेटेड वोल्टेज | 5000V |

| उत्पत्ति का स्थान | जियांगसी, चीन | मॉडल नंबर | ईआईडब्ल्यू |

| ब्रांड नाम | हुआएर्डा | अनुप्रयोग | औद्योगिक मोटर्स और विद्युत उपकरण |

| कंडक्टर प्रकार | ठोस | आकार | गोल |

| तापमान | 180℃ | प्रकार | बचाव |

पैकेजिंग और डिलीवरी

| बेचने वाली इकाइयाँ | किलोग्राम |

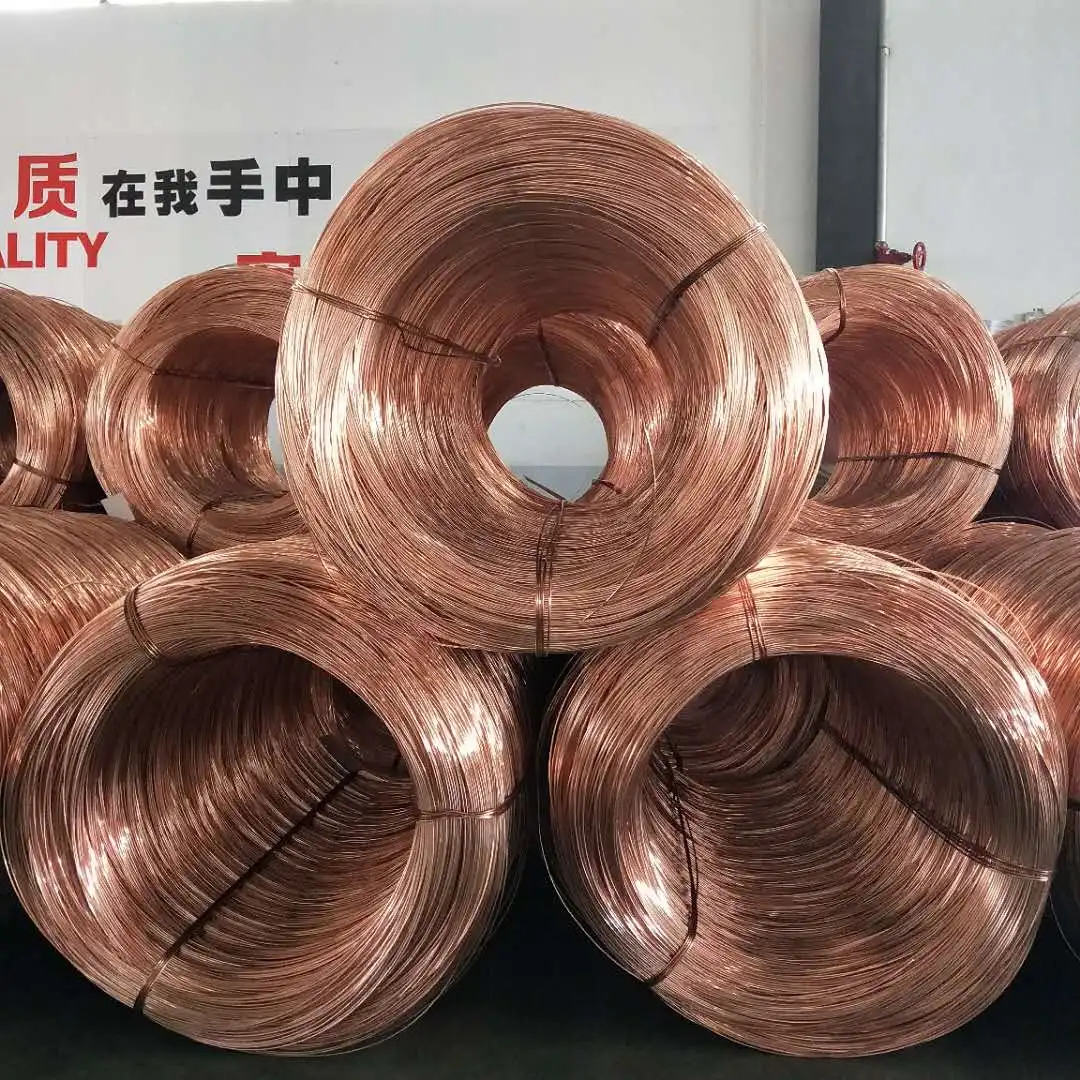

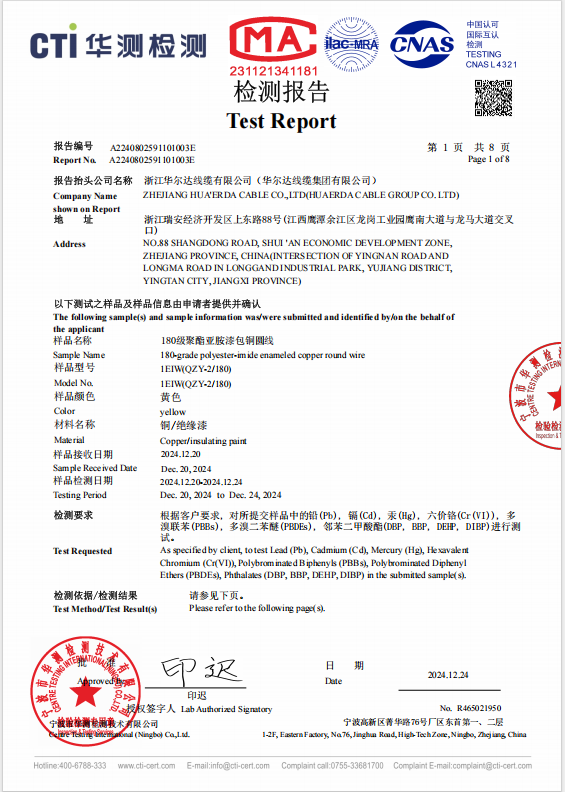

हुआएर्डा एनामेल्ड वायर इलेक्ट्रिकल वायर केबल एक उच्च गुणवत्ता वाला उत्पाद है जो मांग वाली विद्युत और औद्योगिक आवश्यकताओं को पूरा करने के लिए डिज़ाइन किया गया है। इस तार में 1.900 मिमी व्यास के साथ एक बेस तांबा चालक है, जो उत्कृष्ट विद्युत चालनता और टिकाऊपन प्रदान करता है। तांबे पर पॉलिएस्टर इमाइड से बने एनामेल इंसुलेशन की एक सुचारु परत लगाई गई है, जो इसे 180°C तक के उच्च तापमान का सामना करने में सक्षम बनाती है। इसे ऐसे वातावरण में उपयोग करने के लिए उपयुक्त बनाता है जहां ऊष्मा प्रतिरोध महत्वपूर्ण है, जिसमें एयरोस्पेस अनुप्रयोग और अन्य उच्च प्रदर्शन वाले उद्योग शामिल हैं

हुआएर्डा एनामेल्ड तार की सबसे खास विशेषता इसकी 5000 वोल्ट तक के उच्च वोल्टेज को सुरक्षित रूप से संभालने की क्षमता है। इसे विमान इंजनों में सहायक केबल के रूप में उपयोग करने के लिए आदर्श विकल्प बनाता है, जहां विश्वसनीयता और सुरक्षा दोनों महत्वपूर्ण हैं। पॉलिएस्टर इमाइड इन्सुलेशन विद्युत भंग, यांत्रिक घर्षण और रासायनिक जोखिम के खिलाफ मजबूत सुरक्षा प्रदान करता है, जो कठोर परिस्थितियों में भी लंबे समय तक प्रदर्शन की गारंटी देता है

तार के डिजाइन का ध्यान केवल प्रदर्शन पर ही नहीं बल्कि उपयोग में आसानी पर भी है। इसकी लचीलापन तंग स्थानों में आसानी से मोड़ने और मार्गदर्शन की अनुमति देता है, जो अक्सर जटिल मशीनरी या इलेक्ट्रॉनिक उपकरणों में आवश्यक होता है। इसके अतिरिक्त, एनामेल कोटिंग एक चिकनी और सुसंगत परिष्करण प्रदान करती है, जो समय के दौरान लघु परिपथ को रोकने और स्थिर विद्युत संपर्क बनाए रखने में मदद करती है

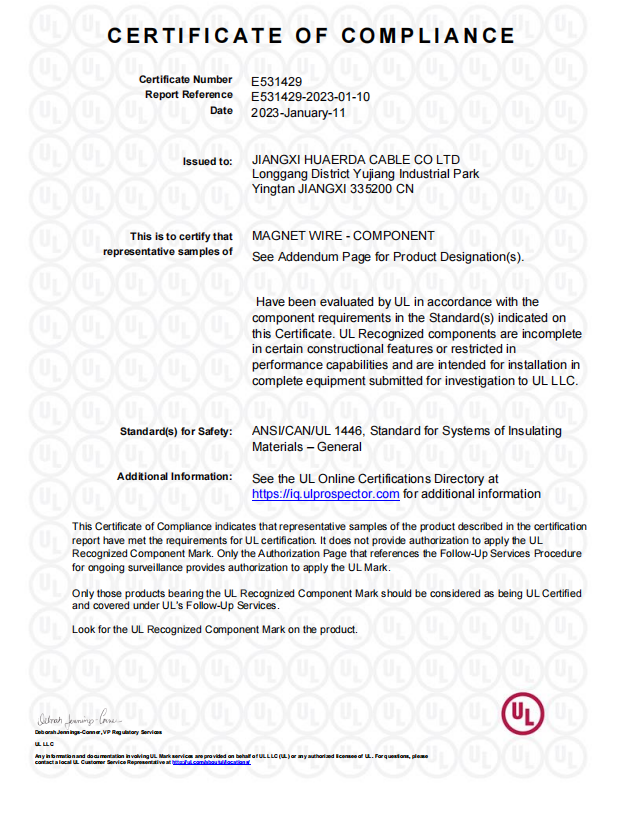

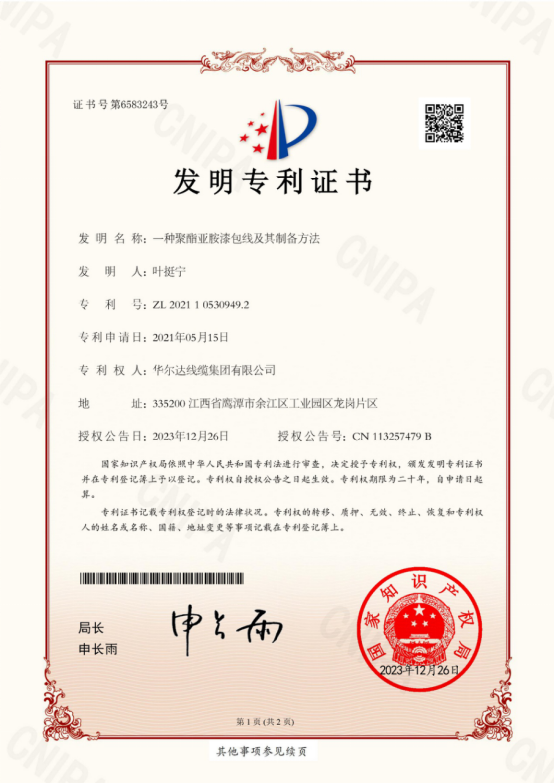

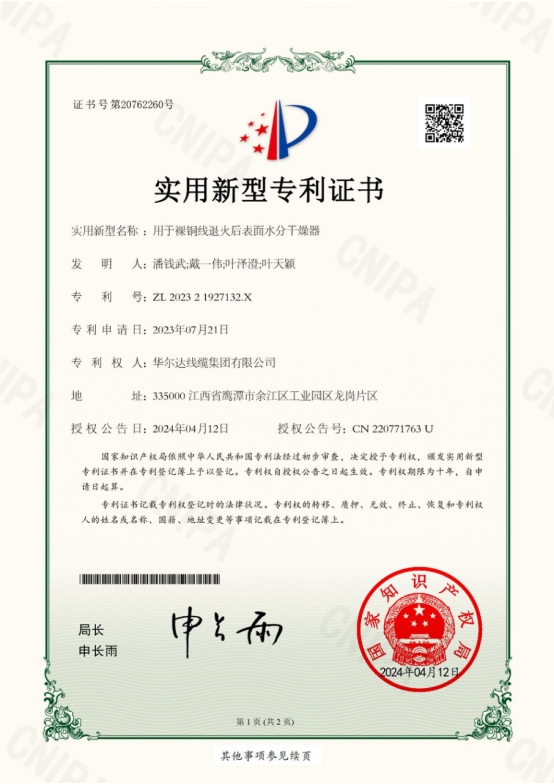

हुआएरडा एक विश्वसनीय ब्रांड है जो भरोसेमंद और टिकाऊ विद्युत घटकों के उत्पादन के लिए जाना जाता है। उनके एनेमल वायर अंतरराष्ट्रीय मानकों को पूरा करने के लिए सख्त गुणवत्ता नियंत्रण से गुजरते हैं, जिससे यह सुनिश्चित होता है कि प्रत्येक रोल लगातार परिणाम दे। चाहे आप मौजूदा उपकरणों की मरम्मत पर काम कर रहे हों या एविएशन, ऑटोमोटिव या औद्योगिक क्षेत्रों में नए विद्युत प्रणालियों की डिजाइन कर रहे हों, यह तार आपके द्वारा लगाई गई मांगों को पूरा कर सकता है

1.900मिमी बेयर कॉपर कंडक्टर और पॉलिएस्टर इमाइड इन्सुलेशन वाला हुआएरडा एनामेल्ड तार उच्च तापमान और उच्च वोल्टेज अनुप्रयोगों के लिए एक उत्कृष्ट विकल्प है। ऊष्मा (अधिकतम 180°C तक) के प्रति उच्च प्रतिरोध और 5000V पर सुरक्षित रूप से संचालित होने की क्षमता के कारण यह विशेष रूप से एयरो इंजन सहायक उपयोगों के लिए उपयुक्त है। तार की मजबूत संरचना और विश्वसनीय इन्सुलेशन यह सुनिश्चित करता है कि चुनौतीपूर्ण वातावरण में भी यह अच्छा प्रदर्शन करे, जिससे यह इंजीनियरों और तकनीशियनों दोनों के लिए एक भरोसेमंद घटक बन जाता है। यदि आपको एक मजबूत, ऊष्मा-प्रतिरोधी और उच्च वोल्टेज वाला विद्युत तार चाहिए, तो हुआएरडा एनामेल्ड तार एक समझदारी भरा समाधान है

याददिलाने:

प्रकार |

पॉलिएस्टर |

संशोधित पॉलिएस्टर |

पॉलीयूरेथेन |

पॉलीयूरेथेन |

पॉलिएस्टर इमाइड |

पॉलिएमाइड-इमाइड |

कोड |

PEW, QZ |

PEW, QZ |

UEW, QA |

UEW, QA |

EIW, QZY |

EI/AIW, QZY/XY |

थर्मल क्लास |

कक्षा B, 130℃ |

कक्षा F, 155℃ |

कक्षा F, 155℃ |

कक्षा H, 180℃ |

कक्षा H, 180℃ |

कक्षा H, 200℃/220℃ |

1. प्रश्न: एनामेल्ड वायर का न्यूनतम व्यास कितना सूक्ष्म हो सकता है

उत्तर: हमारे द्वारा उत्पादित एनामेल्ड तार का सबसे छोटा व्यास 0.060 मिमी तक हो सकता है। हम बुद्धिमान प्रक्रिया नियंत्रण अपनाते हैं ताकि उच्च सटीकता की मांग के तहत भी उत्कृष्ट इन्सुलेशन और उच्च तापमान प्रतिरोध को बनाए रखा जा सके, जिसका उपयोग क्लिक्स, विद्युत उपकरणों, नई ऊर्जा वाहनों, 5 जी संचार आदि के क्षेत्रों में व्यापक रूप से किया जाता है।

3. प्रश्न: क्या कंडक्टर सामग्री उच्च मानकों को पूरा करती है

हम एनील्ड लो-ऑक्सीजन और ऑक्सीजन-मुक्त तांबे के तारों का उपयोग करते हैं, जो ऑक्सीकरण प्रतिरोध और चालकता के मामले में सामान्य तांबे से बेहतर हैं, और उद्योग प्रमाणन से गुजर चुके हैं। उदाहरण के लिए, कंडक्टर की शुद्धता 99.97% है, जो लंबे समय तक उपयोग में कम प्रतिरोध और कम ऊष्मा उत्पादन सुनिश्चित करती है।

4. प्रश्न: ऑर्डर डिलीवरी के लिए लीड टाइम कितना है

उत्तर: स्टॉक के लिए, हम जमा राशि प्राप्त करने के 7 कार्य दिवसों के भीतर माल को लोडिंग पोर्ट तक भेज सकते हैं। उत्पादन अवधि के लिए, आमतौर पर जमा राशि प्राप्त करने के बाद लोडिंग पोर्ट तक माल भेजने में लगभग 15 से 30 दिन लगते हैं

5. प्रश्न: गुणवत्ता समस्याओं से कैसे निपटें

उत्तर: कृपया उत्पाद नमूनों को सुरक्षित रखें और ग्राहक सेवा से संपर्क करें

6. प्रश्न: नमकीन पानी के परीक्षण में कई पिनहोल्स वाले एनामेल्ड वायर क्यों खरीदें

उत्तर: राष्ट्रीय मानक यह उपबंध करता है कि परीक्षण के लिए नमूने लेने का सही तरीका यह है कि पैकेज से निकालते समय नमूने पर तनाव या अनावश्यक मोड़ नहीं आना चाहिए। प्रत्येक परीक्षण से पहले पर्याप्त एनेमल वायर को हटा देना चाहिए ताकि सुनिश्चित हो सके कि नमूने में क्षतिग्रस्त तार के खंड न हों। कभी भी ड्राई वायर को मोड़ें नहीं

7. प्रश्न: प्रतिरोध परीक्षण के परिणाम निर्दिष्ट सीमा से अधिक क्यों हैं?

उत्तर: राष्ट्रीय मानक में 20 डिग्री सेल्सियस पर प्रतिरोध परीक्षण के वातावरण को निर्दिष्ट किया गया है। दक्षिणी क्षेत्रों में मूल परीक्षण के समय अधिकांश समय तापमान 30 डिग्री सेल्सियस से अधिक रहता है और सामान्य ग्राहकों के पास स्थिर तापमान प्रयोगशाला नहीं होती है, इसलिए परीक्षण के परिणाम अधिक आते हैं। या फिर तापमान सूचकांक के अनुसार 20 डिग्री सेल्सियस पर प्रतिरोध में परिवर्तित कर लें।

9. प्रश्न: फाइन तार के उपयोग के दौरान, कई धागे होंगे और धागे को पहचान नहीं पाएंगे

उत्तर: बारीक धागे का तनाव बल अपेक्षाकृत कमजोर होता है, और धागा आसानी से टूट सकता है। बस धागे को हाथ से एक साथ इकट्ठा कर लें (धागे की सतह से कुछ धागा खींचकर निकाल सकते हैं), फिर बेकार लाइन की सतह को धीरे-धीरे इकट्ठा करें, कुछ बेकार लाइन हटा दें, और अंत में एक धागा बन जाएगा। धागा ढूंढना मतलब है कि कुछ बेकार लाइन को हटा देना, बेझिझक इकट्ठा करें, संकोच न करें