Magnet wire and enamel wire are different terms for the same thing; a special type of wire used in electrical devices. It's coated in a thin layer of enamel insulation to prevent the wire's surface from having an electrical discharge. Enamel wire is employed in a variety of electrical devices including motors, transformers and generators. And the reason it's so common is due to its unusual properties and characteristics, which are very useful in electrical applications. Read on to find out more about enamel wire and why it is the preferred type for so many of your electrical requirements.

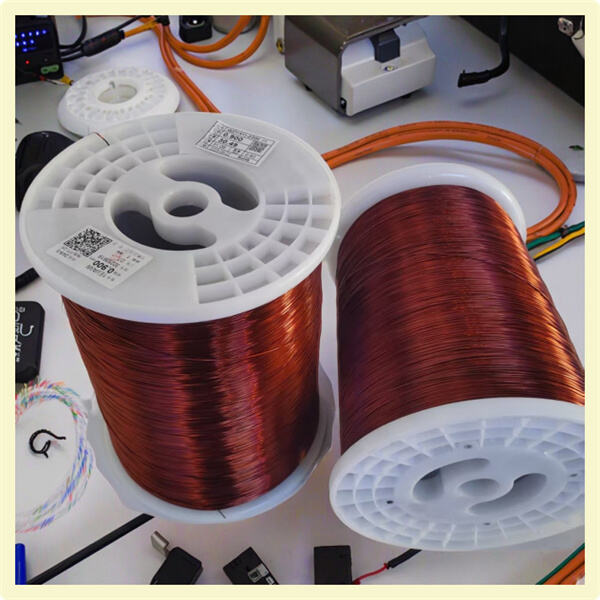

Enamel wire is composed of a copper or aluminum core covered in a very thin layer of insulation. This insulation is generally comprised of a heat resistant enamel or the like having high heat resistance. The Enameled Wire keeps the wire from being damaged and helps to ensure that the electricity can pass through it easily. Enamel wire is available in various gauges or sizes as well as various thicknesses, to suit the intended use in a electrical device.

There are several advantages of Composite Enameled Copper Round Wire for electrical purposes and that is why it is widely preferred. The insulator is one of the primary reasons. The wire's enamel coating helps protect against short circuits and other electrical issues that could result from exposed wiring. Enamel wire is also tough and resistant, giving it the ability to withstand high temperatures, which makes it ideal for those that generate heat, such as, motors and more. Enamel wire is also highly effective in conducting electricity – an important factor when it comes to the proper function and safety of electrical devices.

Enamel wire has many unique properties that make it the best choice for electrical uses. One such property is its flexibility. HUAERDA Enamel wire is very pliable and pliable, so it is very suitable for devices with complex wiring. The wire from enamel is also quite insurable, so that the wire works properly for a long time. Enamel wire is also very effective in conducting electricity: meaning that electric devices that use it can run to highest levels.

HUAERDA Enamel wire has better insulating performance, it is higher than that of plastic insulating layer and impregnated fiber insulated wire, and its heat-resistance temperature is 20 C above than that of paper insulated wire. PVC-coated wire, for instance, is a type of wire often employed for electrical purposes. But, PVC coated wire is less temperature-resistant than enamel wire, when heated, it can be easily destroyed. Enamel wire, conversely, can endure significantly higher temperatures and still retain its insulative properties. This makes it the best option for heat-producing devices, such as motors and transformers.

You have to be very careful working with HUAERDA Polyesterimide Enameled Copper Round Wire wire, you don't want to scratch the insulating coating. The only way to strip enamel wire is by stainless steel with a device called a wire stripper, which was made for this exactly. Just be sure to strip only what you need and leave the rest of the cable insulated. When installing enamel wire on other electronic devices, you must adhere to insulation measures to prevent short circuits, and other issues. You can make your electrical outputs work really well and safely if you get the enameled wire well handled and fit for the job.

Copyright © Hua’erda Cable Group Co., Ltd. All Rights Reserved