Huaerda Factory Wholesale High Quality 0.650mm Polyesterimide Enameled Solid Copper Wire Coil Generators Electrical Wires

Description

Key attributes

| Application | Industrial motors and electrical equipment, automotive and transportation fields, precisi... | Conductor Material | Bare Copper |

| Conductor Type | Solid | Insulation Material | Polyester imide paint |

| Rated voltage | 4800V | Place of Origin | Jiangxi,China |

| Temperature | 180℃ | Shape | Round line |

| Diameter | 0.650mm | Brand Name | HUAERDA |

| Model Number | EIW | Type | insulated |

Packaging and delivery

| Selling Units | kilogram |

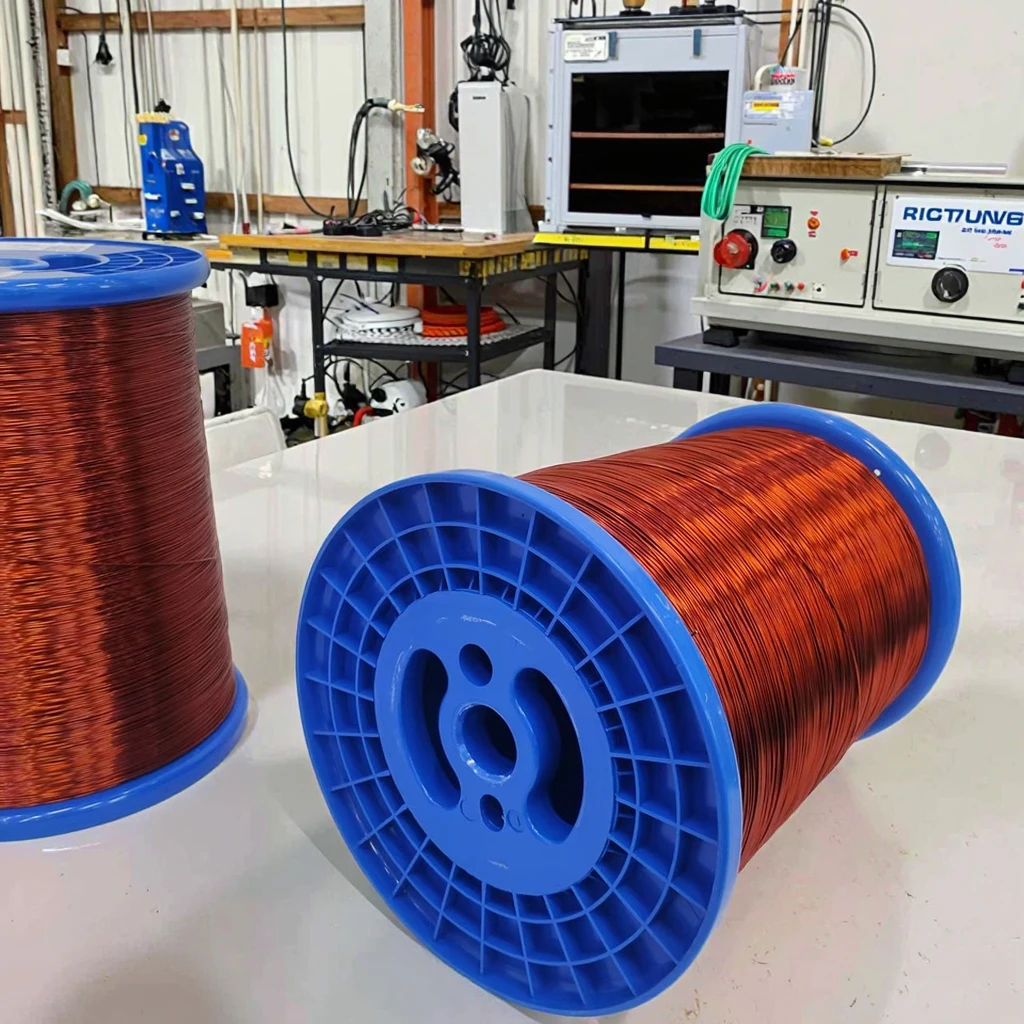

Introducing, the Huaerda Factory Wholesale High Quality 0.650mm Polyesterimide Enameled Solid Copper Wire Coil Generators Electrical Wires. This top-tier product from the trusted brand HUAERDA is a must-have for any electrical project.

Crafted with precision and care, this enameled solid copper wire coil is designed for maximum performance and reliability. The 0.650mm diameter ensures an optimal balance between strength and flexibility, making it ideal for a wide range of applications.

Whether you are working on generators, motors, transformers, or other electrical devices, this copper wire coil is the perfect choice. Its high quality Polyesterimide enamel coating provides excellent insulation and corrosion resistance, ensuring long-lasting durability.

Each coil contains a generous amount of wire, allowing you to complete your project without running out. The solid copper construction provides superior conductivity, ensuring optimal performance for your electrical systems.

Not only does this wire coil perform exceptionally well, but it also boasts a sleek and professional appearance. The copper wire has a clean and uniform finish, making it a visually appealing addition to any project.

Purchasing this product in bulk from HUAERDA's factory wholesale ensures that you get the best value for your money. You can trust in the quality and reliability of this product, knowing that it comes from a reputable and experienced manufacturer.

Upgrade your electrical projects with the Huaerda Factory Wholesale High Quality 0.650mm Polyesterimide Enameled Solid Copper Wire Coil Generators Electrical Wires. Trust in the brand HUAERDA for top-tier products that deliver exceptional performance and durability

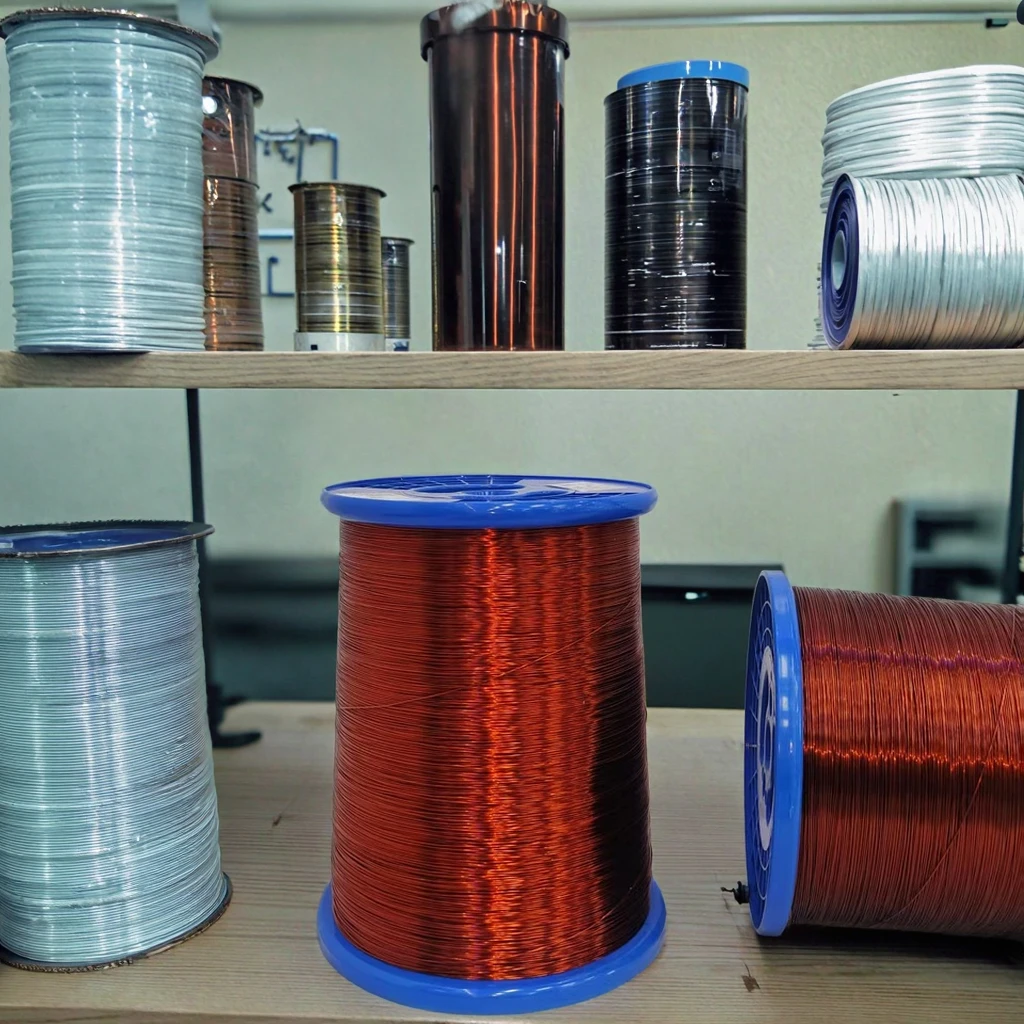

Type |

Polyester |

Modified Polyester |

Polyurethane |

Polyurethane |

Polyesterimide |

Polyamide-imide |

Code |

PEW, QZ |

PEW, QZ |

UEW, QA |

UEW, QA |

EIW, QZY |

EI/AIW, Q - ZY/XY |

Thermal Class |

Class B, 130℃ |

Class F, 155℃ |

Class F, 155℃ |

Class H, 180℃ |

Class H, 180℃ |

Class H, 200℃/220℃ |

1. Q: How fine can the minimum diameter of enameled wire be

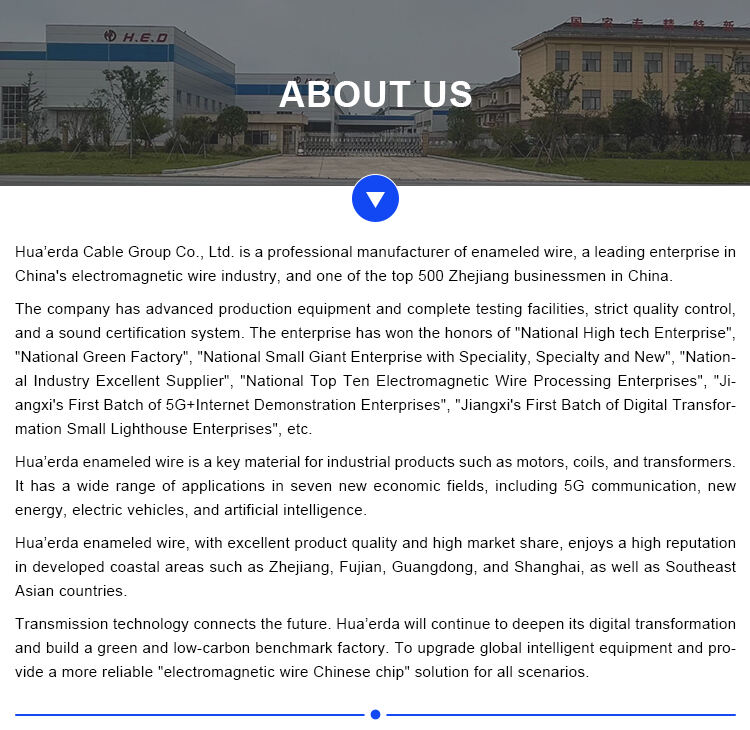

A: The smallest diameter of enameled wire we produce can be up to 0.060 mm. We adopt intelligent process control to ensure that excellent insulation and high temperature resistance can still be maintained under the demand of high precision, which is widely used in the fields of clicks, electrical appliances, new energy vehicles, 5G communication and so on.

2. Q: How to ensure the quality stability of enameled wire

A: We monitor the process parameters in real time through the intelligent production system, and have a number of national invention patents and utility model patented technologies. For example, the multilayer composite enameled wire for 5G communication solves the problem of coating adhesion and has a domestic market share of over 11.2%.

3. Q: Do the conductor materials meet high standards

A: We use annealed low-oxygen and oxygen-free copper wires, which are superior to ordinary copper in terms of oxidation resistance and conductivity, and have passed industry certification. For example, the purity of the conductor is 99.97%, which ensures low resistance and low heat generation in long-term use.

4. Q: How long is the lead time for order delivery

A: For stock, we can ship the goods to the port of loading within 7 working days after we receive the deposit. For production period, it usually takes about 15 days to 30 days to ship the goods to the port of loading after we receive the deposit.

5. Q: How to deal with quality problems

A Please keep the product samples and contact customer service.

6. Q: Why do I buy enameled wire with many pinholes in the salt water test

A: The national standard stipulates that the correct way to take samples for testing is that the specimen should not be subjected to tension or unnecessary bending when it is removed from the package. Before each test, enough enameled wire should be removed to ensure that the specimen does not contain damaged wire segments.

7. Q: Why is the resistance tested, greater than the specified range

A: The national standard specifies the resistance test environment of 20 ℃, the southern region of the basic test time is more than 30 ℃ high temperature weather, and the general customer themselves do not have a constant temperature laboratory, so the test results will be high. Or according to the temperature index converted to 20 ℃ resistance.

8. Q: Why is there a color difference between the two batches of products

A: Enameled wire is the main pursuit of product performance, the color of small differences do not affect the quality, please rest assured that the use.

9. Q: During the use of fine wire, there will be many threads and can't find the threads

A: The stretching force of fine thread is relatively poor, easy to break the thread. Just need to hand all the thread together (can not find the thread of the surface of the thread pulled off some), the surface of the waste line slowly gathered, remove some waste line, and finally will become a thread.