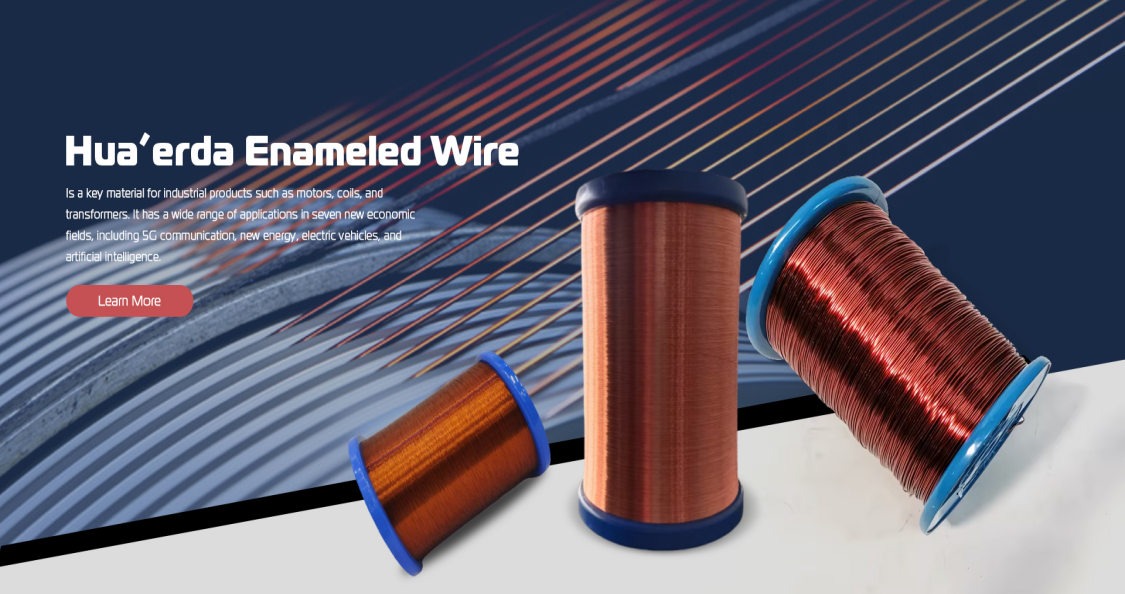

สายลวดทองแดงแบบตัวนำแข็งเคลือบเรซินโพลีเอสเตอร์ ขนาด 0.670 มม. รุ่น Class 155 ของผู้ผลิต Huaerda สำหรับอะแดปเตอร์จ่ายไฟประสิทธิสูง 4800V

คำอธิบาย

คุณสมบัติหลัก

| วัสดุนำไฟฟ้า | ทองแดง | เส้นผ่านศูนย์กลาง | 0.670mm |

| วัสดุฉนวน | สีเคลือบโพลีเอสเตอร์ | แรงดันไฟฟ้าที่กำหนด | 4800V |

| สถานที่ต้นทาง | เจียงซี, จีน | หมายเลขรุ่น | PEWF |

| ชื่อแบรนด์ | HUAERDA | การใช้งาน | มอเตอร์ขนาดเล็กและขนาดกลาง อินเวอร์เตอร์ความถี่ตัวแปร... |

| ประเภทตัวนำ | ของแข็ง | รูปทรง | กลม |

| อุณหภูมิ | 155℃ | ประเภท | ฉนวนกันความร้อน |

การแพ็คและจัดส่ง

| หน่วยที่ขาย | กิโลกรัม |

ลวดเคลือบโพลีเอสเตอร์ทองแดงแท้ ขนาด 0.670 มม. ระดับฉนวน Class 155 จากผู้ผลิต HUAERDA เป็นลวดไฟฟ้าคุณภาพสูงที่ได้รับออกแบบเพื่อตอบสนองความต้องการของอะแดปเตอร์ไฟฟ้าและแอปพลิเคชันไฟฟ้าอื่นๆ ผลิตจากทองแดงแท้ ซึ่งรับประกันการนำไฟฟ้าที่ดีเยี่ยมและความทนทาน ทองแดงที่ใช้ในผลิตภัณฑ์นี้เป็นชนิดตัน หมายว่าให้ประสิทธิภาพและความแข็งแรงที่สม่ำเสมอเมื่ีเทียบกับลวดแบบเส้นเกลียว

หนึ่งในคุณสมบัติสำคัญของลวดชนิดนี้คือการเคลือบด้วยสารโพลีเอสเตอร์อีแนค ซึ่งทำหน้าเป็นชั้นฉนวน ทำให้ลวดสามารถทนต่อแรงดันไฟฟ้าสูงอย่างปลอดภัย—สูงถึง 4800 โวลต์ นอกจากนี้ ฉนวนโพลีเอสเตอร์ยังมีความต้านทานความร้อนที่ดี ทำให้เหมาะสำหรับใช้ในสภาพแวดที่ที่อุณหภูมิสูง ทำให้ลวดหุ้มฉนวนยี่ห้อ HUAERDA เหมาะสำหรับใช้ในอุปกรณ์แปลงไฟฟ้า เครื่องแปลงแรงดัน มอเตอร์ และอุปกรณ์อิเล็กทรอนิกส์อื่นๆ ที่ต้องการการเชื่อมต่อไฟฟ้าที่เชื่อถือได้

ด้วยเส้นผ่านศูนย์กลาง 0.670 มม. ลวดนี้มีความสมดุลที่ดีระหว่างความแข็งแรงและความยืดหยุ่น มีความหนาเพียงพอที่จะนำกระแสไฟฟ้าในระดับสูงโดยไม่เกิดความร้อนเกิน แต่ยังคงมีความยืดหยุ่นเพียงพอที่สามารถดัดและขึ้นรูปได้ง่ายในขั้นตอนการประกอบหรือติดตั้ง ทำให้สะดวกในการใช้งานทั้งผู้ผลิตและช่างเทคนิค เนื่องสามารถใช้ในหลากหลายแบบดีไซน์และการติดตั้งต่างๆ

การที่สายไฟมีค่าความทนทานระดับ Class 155 หมายความว่าสามารถทำงานต่อเนื่องได้ที่อุณหภูมิสูงถึง 155 องศาเซลเซียส โดยไม่เสื่อมสภาพ ซึ่งช่วยให้มั่นใจได้ถึงประสิทธิภาพที่ยาวนานในสภาวะที่ต้องการสูง ลดความเสี่ยงในการเกิดขัดข้องและไม่จำเป็นต้องเปลี่ยนบ่อย นอกจากนี้ ค่าแรงดันไฟฟ้าสูงถึง 4800 โวลต์ ทำให้สายไฟ HUAERDA เป็นตัวเลือกที่ปลอดภัยสำหรับอุปกรณ์ไฟฟ้าที่ทำงานด้วยแรงดันไฟฟ้าสูง จึงให้ความอุ่นใจแก่ผู้ใช้งานในเรื่องความปลอดภัยและความเชื่อถือได้

HUAERDA เป็นที่รู้จักในฐานะผู้ผลิตชิ้นส่วนไฟฟ้าที่มีความน่าเชื่อถือและประสิทธิภาพสูง และลวดทองแดงเคลือบโพลีเอสเตอร์ชนิดนี้ก็ไม่ใช่ข้อยกเว้น มีการผลิตภายใต้มาตรการควบคุมคุณภาพอย่างเข้มงวด เพื่อให้มั่นใจว่าแต่ละม้วนจะเป็นไปตามมาตรฐานอุตสาหกรรมที่เข้มงวด ไม่ว่าคุณจะใช้สร้างอะแดปเตอร์ไฟฟ้า ซ่อมแซมอุปกรณ์ไฟฟ้า หรือพัฒนาแบบอุปกรณ์อิเล็กทรอนิกส์ใหม่ๆ สายไฟนี้ก็ให้ประสิทธิภาพและการใช้งานที่มีความสม่ำเสมอและปลอดภัย

ลวดเคลือบอีนาเมลทองแดงบริสุทธิ์ขนาด 0.670 มม. รุ่น Class 155 จากผู้ผลิต HUAERDA เป็นลวดที่ทนทาน ทนความร้อนได้ดี และมีประสิทธิภาพสูง เหมาะอย่างยิ่งสำหรับการใช้งานทางไฟฟ้าแรงสูง แกนทองแดงบริสุทธิ์ ฉนวนโพลีเอสเตอร์ และโครงสร้างที่มีคุณภาพ ทำให้เป็นตัวเลือกที่ยอดเยี่ยมสำหรับอะแดปเตอร์พลังงานและอุปกรณ์ไฟฟ้าอื่นๆ อีกมากมาย เลือก HUAERDA เพื่อให้ได้ลวดที่ทำงานได้อย่างมีประสิทธิภาพภายใต้แรงกดดัน และสามารถยืนหยัดยาวนานตามกาลเวลา

ประเภท |

โพลีเอสเตอร์ |

โพลีเอสเตอร์ที่ modificar |

โพลียูรีเทน |

โพลียูรีเทน |

โพลีเอสเตอร์อิมายด์ |

โพลีอไมด์-อิมายด์ |

รหัส |

PEW, QZ |

PEW, QZ |

UEW, QA |

UEW, QA |

EIW, QZY |

EI/AIW, Q - ZY/XY |

ชั้นความร้อน |

คลาส B, 130℃ |

คลาส F, 155℃ |

คลาส F, 155℃ |

คลาส H, 180℃ |

คลาส H, 180℃ |

คลาส H, 200℃/ 220℃ |

1. คำถาม: ลวดเคลือบอีนาเมลสามารถมีเส้นผ่านศูนย์กลางเล็กสุดได้ขนาดไหน

A: เส้นผ่าศูนย์กลางที่เล็กที่สุดของลวดเคลือบฉนวนที่เราผลิตสามารถทำได้เล็กถึง 0.060 มม. เราใช้ระบบควบคุมกระบวนการอัจฉริยะเพื่อให้แน่ใจว่าสามารถรักษาน้ำหนักฉนวนและความทนทานต่ออุณหภูมิสูงไว้ได้ แม้ภายใต้ความต้องการที่ต้องการความแม่นยำสูง ซึ่งถูกนำไปใช้กันอย่างแพร่หลายในสาขาต่างๆ เช่น รีเลย์ เครื่องใช้ไฟฟ้า ยานยนต์พลังงานใหม่ 5G การสื่อสาร เป็นต้น

2. Q: วิธีการรับประกันเสถียรภาพของคุณภาพของลวดเคลือบอีนาเมล

A: เราตรวจสอบพารามิเตอร์กระบวนการแบบเรียลไทม์ผ่านระบบการผลิตอัจฉริยะ และเรามีสิทธิบัตรการประดิษฐ์แห่งชาติและเทคโนโลยีสิทธิบัตรทาง_utility จำนวนมาก เช่น ลวดเคลือบอีนาเมลหลายชั้นสำหรับการสื่อสาร 5G แก้ปัญหาการยึดเกาะของชั้นเคลือบและมีส่วนแบ่งตลาดในประเทศมากกว่า 11.2%.

3. Q: วัสดุนำไฟฟ้าตรงตามมาตรฐานสูงหรือไม่

A: เราใช้ลวดทองแดงที่ผ่านกระบวนการอบอ่อนและไม่มีออกซิเจน ซึ่งมีคุณภาพเหนือกว่าทองแดงทั่วไปในด้านการต้านทานการเกิดออกซิเดชันและความนำกระแสไฟฟ้า และได้รับการรับรองจากอุตสาหกรรมแล้ว เช่น ความบริสุทธิ์ของตัวนำอยู่ที่ 99.97% ซึ่งรับประกันว่าจะมีความต้านทานต่ำและเกิดความร้อนต่ำเมื่อใช้งานระยะยาว

4. Q: เวลาในการส่งมอบคำสั่งซื้อนานเท่าไร

A: สำหรับสินค้าในสต็อก เราสามารถจัดส่งสินค้าไปยังท่าเรือโหลดภายใน 7 วันทำการหลังจากเราได้รับเงินมัดจำ ส่วนระยะเวลาการผลิต ปกติจะใช้เวลาประมาณ 15 ถึง 30 วันในการจัดส่งสินค้าไปยังท่าเรือโหลดหลังจากเราได้รับเงินมัดจำ

5. Q: ควรทำอย่างไรเมื่อพบปัญหาด้านคุณภาพ

A กรุณาเก็บตัวอย่างสินค้าและติดต่อฝ่ายบริการลูกค้า

6. คำถาม: เหตุใดฉันจึงซื้อสายไฟเคลือบอีนาเมลที่มีรูพรุนจำนวนมากในทดสอบด้วยน้ำเกลือ

A: มาตรฐานแห่งชาติกำหนดไว้ว่า วิธีที่ถูกต้องในการสุ่มตัวอย่างเพื่อการทดสอบคือ ตัวอย่างที่นำมาทดสอบจะต้องไม่ถูกดึงหรืองอจนเกินความจำเป็นในขณะที่นำออกจากบรรจุภัณฑ์ ก่อนการทดสอบแต่ละครั้ง จะต้องดึงลวดเคลือบออกให้เพียงพอ เพื่อให้แน่ใจว่าตัวอย่างไม่มีส่วนของลวดที่เสียหายปะปนอยู่

7. คำถาม: เหตุใดค่าความต้านทานที่ทดสอบได้จึงมากกว่าช่วงที่กำหนด

คำตอบ: มาตรฐานแห่งชาติกำหนดสภาพแวดล้อมในการทดสอบความต้านทานที่ 20 ℃ ในภูมิภาคตอนใต้ เวลาทดสอบพื้นฐานมักจะอยู่ในอากาศร้อนกว่า 30 ℃ และโดยทั่วไปลูกค้าเองไม่มีห้องปฏิบัติการควบคุมอุณหภูมิ ดังนั้นผลการทดสอบจึงอาจสูงกว่าปกติ หรือสามารถแปลงตามดัชนีอุณหภูมิเป็นความต้านทานที่ 20 ℃ ได้

8. คำถาม: เหตุใดจึงมีความแตกต่างของสีระหว่างสองชุดสินค้า

A: ลวดเคลือบอีนาเมลเป็นการเน้นที่ประสิทธิภาพของผลิตภัณฑ์ สีที่แตกต่างกันเล็กน้อยไม่ส่งผลกระทบต่อคุณภาพ โปรดใช้งานได้อย่างสบายใจ

9. Q: ในระหว่างการใช้งานลวดบาง จะมีเส้นด้ายจำนวนมากและไม่สามารถหาเส้นด้ายได้

ข้อ A: แรงดึงของเส้นด้ายเล็กค่อนข้างอ่อน ทำให้เส้นด้ายขาดได้ง่าย เพียงแค่ใช้มือรวบเส้นด้ายทั้งหมดเข้าด้วยกัน (อาจไม่พบเส้นด้ายบนผิวที่หลุดออกมาบ้าง) เส้นด้ายที่เป็นของเสียจะค่อยๆ รวมตัวกัน ให้ดึงเส้นด้ายที่ไม่ใช้แล้วออกบางส่วน สุดท้ายจะกลายเป็นเส้นด้ายที่ใช้การได้ การค้นหาเส้นด้ายนี้คือการเอาเส้นด้ายที่ไม่ใช้แล้วออกบางส่วน โปรดมั่นใจและเก็บรวบรวมได้อย่างกล้าหาญ