ลวดไฟฟ้า Huaerda ขนาด 0.670 มม. EIW ตัวนำตัน ลวดทองแดงเคลือบ สายเคเบลขดลวด ผลิตในจีน จัดจำหน่ายโดยโรงงานโดยตรง

คำอธิบาย

คุณสมบัติหลัก

| วัสดุนำไฟฟ้า | Bare copper | เส้นผ่านศูนย์กลาง | 0.670mm |

| วัสดุฉนวน | สีเคลือบโพลีเอสเตอร์อิมไมด์ | แรงดันไฟฟ้าที่กำหนด | 4800V |

| สถานที่ต้นทาง | เจียงซี ประเทศจีน | หมายเลขรุ่น | EIW |

| ชื่อแบรนด์ | HUAERDA | การใช้งาน | มอเตอร์อุตสาหกรรมและอุปกรณ์ไฟฟ้า |

| ประเภทตัวนำ | ของแข็ง | รูปทรง | ลวดกลม |

| อุณหภูมิ | 180℃ | ประเภท | ฉนวนกันความร้อน |

การแพ็คและจัดส่ง

| หน่วยที่ขาย | กิโลกรัม |

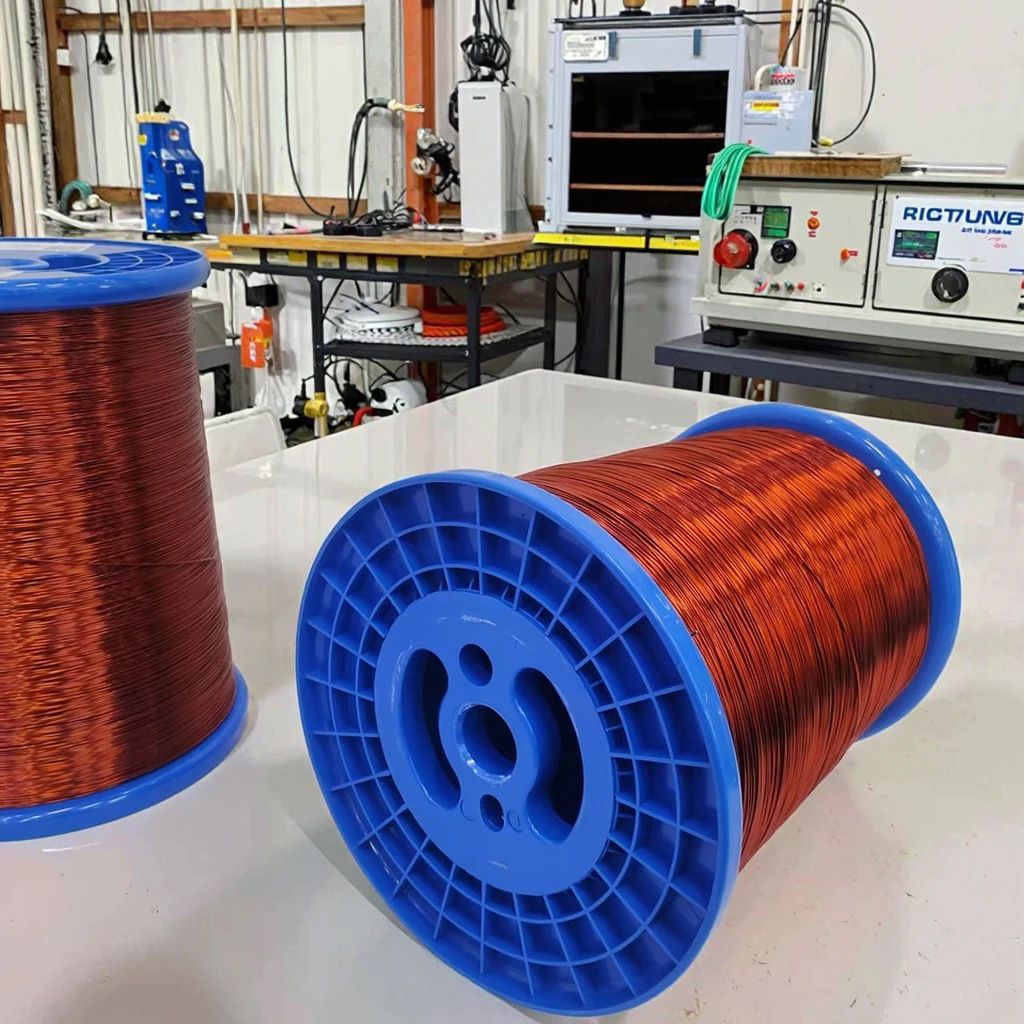

ขอแนะนำ ลวดไฟฟ้า EIW ขนาด 0.670 มม. ผลิตในประเทศจีน โดย HUAERDA ที่ขายตรงจากโรงงาน ซึ่งเป็นตัวเลือกที่เชื่อถือได้และมีคุณภาพสูงสำหรับความต้องการด้านสายไฟฟ้าของคุณ ตัวนำแบบแข็งเหล่านี้ทำจากลวดทองแดงเคลือบฉนวน ออกแบบมาโดยเฉพาะสำหรับการใช้งานพันขดลวดและสายเคเบิล ไม่ว่าคุณจะทำงานเกี่ยวกับมอเตอร์ เครื่องแปลงแรงดัน คอยล์ หรือโครงการไฟฟ้าอื่น ๆ ลวดของ HUAERDA จะให้ประสิทธิภาพและความทนทานที่ยอดเยี่ยม

HUAERDA แบรนด์ที่ได้รับความไว้วางใจในอุตสาหกรรมสายไฟฟ้า รับประกันว่าสายไฟแต่ละเส้นถูกผลิตขึ้นอย่างพิถีพิถันเพื่อให้เป็นไปตามมาตรฐานคุณภาพที่เข้มงวด ความหนา 0.670 มม. เหมาะอย่างยิ่งสำหรับงานพันหลากหลายประเภท ให้การนำไฟฟ้าได้ดี และทนทานต่อความร้อน ฉนวนเคลือบอีนาเมลบนลวดทองแดงไม่เพียงแต่ช่วยปกป้องตัวลวดเอง แต่ยังช่วยป้องกันการลัดวงจรและสัญญาณรบกวนทางไฟฟ้า ทำให้งานของคุณปลอดภัยและมีประสิทธิภาพมากยิ่งขึ้น

หนึ่งในข้อดีหลักของสายไฟฟ้า EIW (Enameled Insulated Wire) เหล่านี้คือการออกแบบตัวนำแบบเส้นเดี่ยว (solid conductor) สายไฟแบบเส้นเดี่ยวมีชื่อเสียงในด้านความมั่นคงและความสามารถในการรองรับแรงเครียดทางกลที่สูงกว่า ทำให้เหมาะสำหรับการพันในพื้นที่จำกัดหรือชิ้นส่วนไฟฟ้าขนาดกะทัดรัด การใช้ตัวนำแบบเส้นเดี่ยวนี้ช่วยให้มั่นใจได้ว่าการติดตั้งระบบสายไฟของคุณจะคงทนและเชื่อถือได้ตลอดเวลา แม้ในสภาวะที่ต้องเผชิญกับความต้องการที่สูง

ลวดของ HUAERDA ผลิตโดยตรงจากโรงงานในประเทศจีน โดยการตัดขั้นตอนคนกลางออกไป คุณจึงได้รับราคาจากโรงงานโดยตรงโดยไม่ลดทอนคุณภาพ การขายโดยตรงนี้หมายความว่าคุณจะได้รับลวดทองแดงเคลือบคุณภาพสูงในราคาที่แข่งขันได้ ทำให้เป็นตัวเลือกที่คุ้มค่าสำหรับผู้ผลิต ช่างไฟฟ้า และผู้ที่ชื่นชอบงานประดิษฐ์

ลวดเหล่านี้ใช้งานง่ายเนื่องจากมีชั้นเคลือบเรียบเนียน ซึ่งช่วยให้สามารถพันได้อย่างเป็นระเบียบและแน่นหนา โดยไม่เกิดการติดหรือแตกร้าว ขนาด 0.670 มม. มีความยืดหยุ่นเพียงพอสำหรับการใช้งานหลากหลาย ทำให้คุณสามารถนำไปใช้ในโครงการต่างๆ ได้อย่างคล่องตัว โดยไม่จำเป็นต้องใช้ลวดหลายขนาด

ลวดไฟฟ้า EIW ขนาด 0.670 มม. จากโรงงานโดยตรงของ HUAERDA เป็นทางออกที่น่าเชื่อ มีประสิทธิภาพ และมีต้นทุนต่ำสำหรับทุกคนที่ต้องการลวดทองแดงหุ้มฉนวนแบบตัวนำแบบแข็งเพื่อการพันและใช้ในสายเคเบิล ด้วยการนำไฟฟ้าที่ยอดเยี่ยม ฉนวนที่ดี และราคาจากโรงงานโดยตรง ทำให้เป็นตัวเลือกอัจฉริยะสำลูกค้าที่ใส่ใจคุณภาพและต้องการคุณค่าที่ดีที่สุด เลือก HUAERDA สำหรับโครงการเดินสายไฟฟ้าครั้งต่อไปของคุณ และสัมผีความสมร์รที่แท้จริงและความน่าเชื่อ

ประเภท |

โพลีเอสเตอร์ |

โพลีเอสเตอร์ที่ modificar |

โพลียูรีเทน |

โพลียูรีเทน |

โพลีเอสเตอร์อิมายด์ |

โพลีอไมด์-อิมายด์ |

รหัส |

PEW, QZ |

PEW, QZ |

UEW, QA |

UEW, QA |

EIW, QZY |

EI/AIW, Q - ZY/XY |

ชั้นความร้อน |

คลาส B, 130℃ |

คลาส F, 155℃ |

คลาส F, 155℃ |

คลาส H, 180℃ |

คลาส H, 180℃ |

คลาส H, 200℃/ 220℃ |

1. คำถาม: ลวดเคลือบอีนาเมลสามารถมีเส้นผ่านศูนย์กลางเล็กสุดได้ขนาดไหน

A: เส้นผ่าศูนย์กลางที่เล็กที่สุดของลวดเคลือบฉนวนที่เราผลิตสามารถทำได้เล็กถึง 0.060 มม. เราใช้ระบบควบคุมกระบวนการอัจฉริยะเพื่อให้แน่ใจว่าสามารถรักษาน้ำหนักฉนวนและความทนทานต่ออุณหภูมิสูงไว้ได้ แม้ภายใต้ความต้องการที่ต้องการความแม่นยำสูง ซึ่งถูกนำไปใช้กันอย่างแพร่หลายในสาขาต่างๆ เช่น รีเลย์ เครื่องใช้ไฟฟ้า ยานยนต์พลังงานใหม่ 5G การสื่อสาร เป็นต้น

2. Q: วิธีการรับประกันเสถียรภาพของคุณภาพของลวดเคลือบอีนาเมล

A: เราตรวจสอบพารามิเตอร์กระบวนการแบบเรียลไทม์ผ่านระบบการผลิตอัจฉริยะ และเรามีสิทธิบัตรการประดิษฐ์แห่งชาติและเทคโนโลยีสิทธิบัตรทาง_utility จำนวนมาก เช่น ลวดเคลือบอีนาเมลหลายชั้นสำหรับการสื่อสาร 5G แก้ปัญหาการยึดเกาะของชั้นเคลือบและมีส่วนแบ่งตลาดในประเทศมากกว่า 11.2%.

3. Q: วัสดุนำไฟฟ้าตรงตามมาตรฐานสูงหรือไม่

A: เราใช้ลวดทองแดงที่ผ่านกระบวนการอบอ่อนและไม่มีออกซิเจน ซึ่งมีคุณภาพเหนือกว่าทองแดงทั่วไปในด้านการต้านทานการเกิดออกซิเดชันและความนำกระแสไฟฟ้า และได้รับการรับรองจากอุตสาหกรรมแล้ว เช่น ความบริสุทธิ์ของตัวนำอยู่ที่ 99.97% ซึ่งรับประกันว่าจะมีความต้านทานต่ำและเกิดความร้อนต่ำเมื่อใช้งานระยะยาว

4. Q: เวลาในการส่งมอบคำสั่งซื้อนานเท่าไร

A: สำหรับสินค้าในสต็อก เราสามารถจัดส่งสินค้าไปยังท่าเรือโหลดภายใน 7 วันทำการหลังจากเราได้รับเงินมัดจำ ส่วนระยะเวลาการผลิต ปกติจะใช้เวลาประมาณ 15 ถึง 30 วันในการจัดส่งสินค้าไปยังท่าเรือโหลดหลังจากเราได้รับเงินมัดจำ

5. Q: ควรทำอย่างไรเมื่อพบปัญหาด้านคุณภาพ

A กรุณาเก็บตัวอย่างสินค้าและติดต่อฝ่ายบริการลูกค้า

6. คำถาม: เหตุใดฉันจึงซื้อสายไฟเคลือบอีนาเมลที่มีรูพรุนจำนวนมากในทดสอบด้วยน้ำเกลือ

A: มาตรฐานแห่งชาติกำหนดไว้ว่า วิธีที่ถูกต้องในการสุ่มตัวอย่างเพื่อการทดสอบคือ ตัวอย่างที่นำมาทดสอบจะต้องไม่ถูกดึงหรืองอจนเกินความจำเป็นในขณะที่นำออกจากบรรจุภัณฑ์ ก่อนการทดสอบแต่ละครั้ง จะต้องดึงลวดเคลือบออกให้เพียงพอ เพื่อให้แน่ใจว่าตัวอย่างไม่มีส่วนของลวดที่เสียหายปะปนอยู่

7. คำถาม: เหตุใดค่าความต้านทานที่ทดสอบได้จึงมากกว่าช่วงที่กำหนด

คำตอบ: มาตรฐานแห่งชาติกำหนดสภาพแวดล้อมในการทดสอบความต้านทานที่ 20 ℃ ในภูมิภาคตอนใต้ เวลาทดสอบพื้นฐานมักจะอยู่ในอากาศร้อนกว่า 30 ℃ และโดยทั่วไปลูกค้าเองไม่มีห้องปฏิบัติการควบคุมอุณหภูมิ ดังนั้นผลการทดสอบจึงอาจสูงกว่าปกติ หรือสามารถแปลงตามดัชนีอุณหภูมิเป็นความต้านทานที่ 20 ℃ ได้

8. คำถาม: เหตุใดจึงมีความแตกต่างของสีระหว่างสองชุดสินค้า

A: ลวดเคลือบอีนาเมลเป็นการเน้นที่ประสิทธิภาพของผลิตภัณฑ์ สีที่แตกต่างกันเล็กน้อยไม่ส่งผลกระทบต่อคุณภาพ โปรดใช้งานได้อย่างสบายใจ

9. Q: ในระหว่างการใช้งานลวดบาง จะมีเส้นด้ายจำนวนมากและไม่สามารถหาเส้นด้ายได้

ข้อ A: แรงดึงของเส้นด้ายเล็กค่อนข้างอ่อน ทำให้เส้นด้ายขาดได้ง่าย เพียงแค่ใช้มือรวบเส้นด้ายทั้งหมดเข้าด้วยกัน (อาจไม่พบเส้นด้ายบนผิวที่หลุดออกมาบ้าง) เส้นด้ายที่เป็นของเสียจะค่อยๆ รวมตัวกัน ให้ดึงเส้นด้ายที่ไม่ใช้แล้วออกบางส่วน สุดท้ายจะกลายเป็นเส้นด้ายที่ใช้การได้ การค้นหาเส้นด้ายนี้คือการเอาเส้นด้ายที่ไม่ใช้แล้วออกบางส่วน โปรดมั่นใจและเก็บรวบรวมได้อย่างกล้าหาญ