ខ្សែកូប៉ាល់មូលគុណភាពខ្ពស់ 1.000mm អ្នកនាំសុទ្ធ មានស្រាប់ប៉ូលីអេស្ទែរអ៊ីម៉ីត និងការកែប្រែស្រទាប់ការពារប៉ូលីអេម៉ីត

ការពិពណ៌នា

លក្ខណៈសំខាន់

| សំណុំអ៊ីលិច | Copper Bare | អង្កត់ផ្ចិត | 1.000mm |

| មាតិកាពុកព្រះ | ថ្នាំកូតពីឡូអាម៉ីដ អ៊ីមីត | កម្លាំងប្រតិបត្តិការ | 5000V |

| កន្លែងកំណើត | ជៀងស៊ី ចិន | លេខម៉ូដែល | EI/AIW |

| ឈ្មោះម៉ាក | HUAERDA | ការដាក់ពាក្យ | សំភារៈត្រជាក់,ម៉ូទ័រឧស្សាហកម្ម, អគ្គិនី |

| ប្រភេទសំណុំ | ម៉ាស់ | រាង | បន្ទាត់រ៉ូន |

| អุณ្តាសន្ធត់ | 200℃ | ប្រភេទ | បានបញ្ចប់ដោយអ៊ីស៊ូឡេត |

កំពុង និង ដឹកជញ្ជាំ

| តាមុណីទិញ | គីឡូក្រាម |

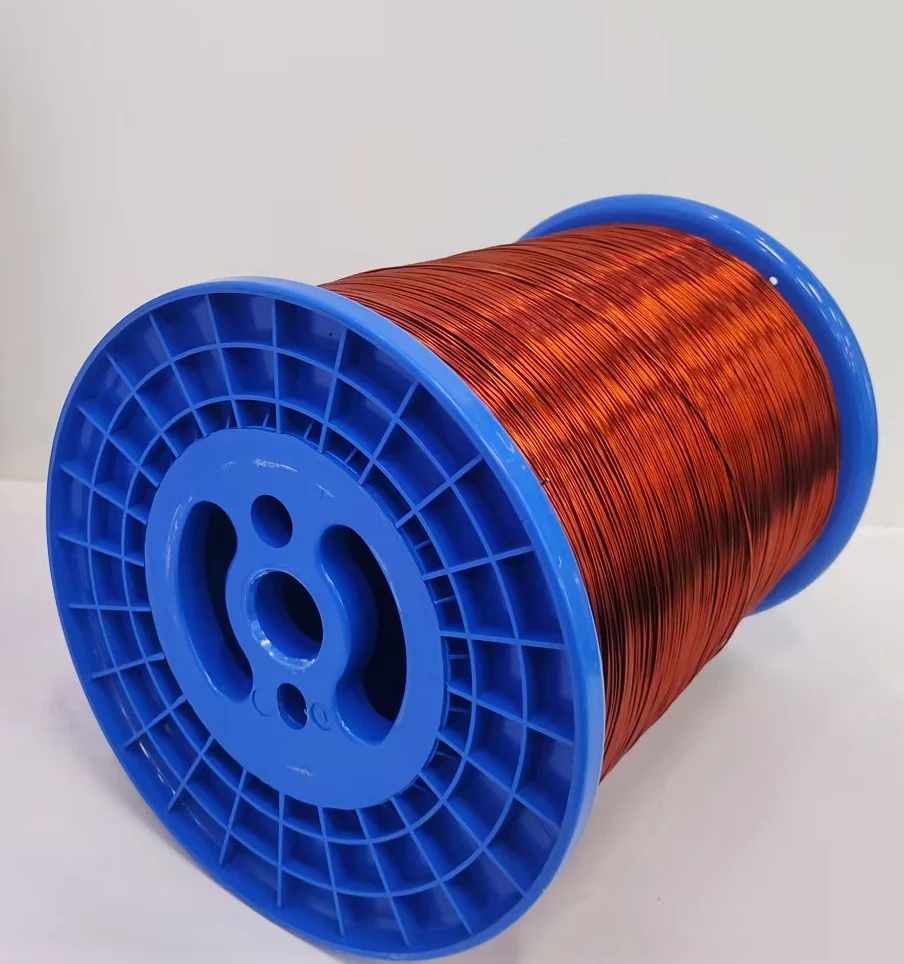

ណែនាំ ខ្សែកូប្រាមូល HUAERDA 1.000mm ដែលមានគុណភាពខ្ពស់ ជាជម្រើសដ៏អាចទុកចិត្ត និងធន់ សម្រាប់កម្មវិធីអគ្គិសនី និងអេឡេកត្រូនិចជាច្រើន។ ផលិតពីខ្សែកូប្រាគ្មិនសំបករឹង ខ្សែនេះមានរូបរាងមូល និងមានអង្កត់ផ្ចៀង 1.000mm ដ៏ជាក់លាក់ ធានាប្រសិទ្ធភាពស្ថិរ និងងាយស្រួលក្នុងការប្រើប្រាស់។

អ្វីដែលធ្វើឱាក់ខ្សែកូប្រែនេះខុសពីគេគឺស្រទាប់គ្របដែលទំនើប។ វាត្រូវបានការពារដោយស្រទាប់គ្របពិសេសដែលមាន polyester imide និង polyamide imide ដែលបានកែប្រែដោយ polyester។ ស្រទាប់គ្របពិសេសនេះបង្កើនភាពធន់ ភាពធន់ទ្រាំនឹងកំដៅ និងលក្ខណៈអ៊ីសូឡង់អគ្គិសនីរបស់ខ្សែ ធ្វើឱាខ្សែសមសម្រាប់បរិស្ថានតម្រូវខ្ពស់ ដែលភាពអាចទុកចិត្តគឺជាកត្តាសំខាន់។ ស្រទាប់គ្របត្រូវបានលាបដោយប្រុងប្រយ័ត្ន ដើម្បីផ្តល់ការការពារល្អប្រឆាំងនឹងការខូច គីមី និងកំដៅ ជួយបន្លាយអាយុកាលខ្សែ និងរក្សាសមត្ថភាពរបស់វាជាលើការបន្ត។

HUAERDA បានរចនាខ្សែកូប្រែនេះដើម្បីបំពេញតម្រូវរបស់អ្នកជំនាញ និងអ្នកចូលចិត្តទាំងពីរ។ មិនថាអ្នកកំពុងធ្វើការលើម៉ូទ័រ ត្រាស្វូរ កូអ៊ីល ឬឧបករណ៍អគ្គិសនីផ្សេងទៀត ខ្សែនេះផ្តល់ការវ៉ែនដោយរលូន និងអ៊ីសូឡង់ដែលស្ថិរ។ ផ្ទៃរបស់ស្រទាប់គ្របរលូន ធ្វើឱាវាងាយក្នុងការប្រើប្រាស់ក្នុងអំឡុក កាត់បន្ថយឱកាសនៃការខូច ឬសៀគ្វីខ្លី។

ដោយសារតម្រូវការខ្ពស់របស់វាសម្រាប់ធាតុប្រាក្រាហ្វឹក ខ្សែក្រវាត់ក្រហម HUAERDA 1.000mm ផ្តល់នូវសក្តានុពលអគ្គិសនីដ៏ល្អ។ នេះមានន័យថាការបាត់បង់ថាមពលតិច និងការបញ្ជូនអគ្គិសនីដោយប្រសិទ្ធភាព ដែលសំខាន់សម្រាប់គម្រោងតូច និងការប្រើប្រាស់ឧស្សាហ៍កម្មធំ។ រចនាសម្ព័ន្ធទំន័ររបស់វាធានានូវភាពរឹង និងស្ថេរភាពក្រោមសម្ពាធមេកានិច ដែលធ្វើឱ្យវាជាជម្រើសល្អសម្រាប់កម្មវិធីដែលត្រូវការគ្រឿងបន្លាស់ដែលមានអាយុយូរ។

ខ្សែក្រវាត់ក្រហមនេះត្រូវបានរចនាក៏ដើម្បីបំពេញស្តង់ដាការងារតឹងរ៉ឹង ដែលឆ្លើយបញ្ជាក់ពីការប្តេជ្ញាចិត្តរបស់ HUAERDA ចំពោះគុណភាព និងសុវត្ថភាព។ ការរួមបញ្ចូលរវាងក្រវាត់ក្រហមរឹង និងស្រទាប់ការពារដ៏ខ្ពស់ផ្តល់នូវភាពស្ងប់ចិត្តដោយដឹងថាអ្នកកំពុងប្រើផលិតផលដែលដំណើរការល្អ ទោះបីនៅក្នុងបរិស្ថានលំបាក។

ខ្សែកូប៉ាលេខ HUAERDA ដែលមានគុណភាពខ្ពស់ 1.000mm ជាមួយនឹងស្រទាប់គ្របដោយ polyester imide និង polyamide imide modified polyester ផ្តល់នូវតុល្យភាពល្អឥតខ្ចោះរវាងភាពរឹងមាំ ការដំណើរចរន្តអគ្គិសនី និងការការពារ។ វាជាជម្រើសដ៏ល្អសម្រាប់អ្នកដែលកំពុងស្វែងរកខ្សែកូប៉ាល់ដែលអាចទុកចិត្តបាន ដែលអាចទប់ទល់នឹងកំដៅ ធន់នឹងការខូច ហើយផ្តល់នូវការដាច់សរសៃអគ្គិសនីដ៏ល្អប្រសើរ។ ជ្រើសរើស HUAERDA សម្រាប់គម្រោងអគ្គិសនីរបស់អ្នក ហើយទទួលបានបទពិសោធន៍នឹងខ្សែកូប៉ាល់ដែលមានគុណភាពខ្ពស់ និងត្រូវបានផលិតឡើងដើម្បីឱ្យប្រើប្រាស់បានយូរ

ប្រភេទ |

Polyester |

Ployisṭer ដែលត្រូវបានកែសម្រួល |

Polyurethane |

Polyurethane |

Ployesṭerimaid |

Ployamid-imaid |

លេខកូដ |

PEW, QZ |

PEW, QZ |

UEW, QA |

UEW, QA |

EIW, QZY |

EI/AIW, Q - ZY/XY |

ថ្នាំប្រភេទ |

ថ្នាំ B, 130℃ |

ថ្នាំ F, 155℃ |

ថ្នាំ F, 155℃ |

ថ្គីម៉ា H, 180℃ |

ថ្គីម៉ា H, 180℃ |

ថ្នាំ H, 200℃/ 220℃ |

1. សំ: តើអង្កត់ផ្ចិតអប្បបរមារបស់ខ្យល់ដែលធ្វើពីថ្មីអាចនៅក្នុងទិសណាដែរ?

A: ខ្សែដែលមានប្រភេទថ្នាំកូតតូចបំផុតដែលយើងផលិតអាចទៅដល់ 0.060 មីល្លីម៉ែត្រ។ យើងប្រើប្រាស់នូវប្រព័ន្ធគ្រប់គ្រងដោយស្វ័យប្រវត្តិ ដើម្បីធានានូវគុណភាពខ្ពស់ និងការទប់ទល់នឹងកំដៅបានល្អ ដោយគ្មានការខូចខាតនៅពេលតម្រូវឲ្យមានភាពត្រឹមត្រូវខ្ពស់។ វាត្រូវបានប្រើប្រាស់យ៉ាងទូលំទូលាយនៅក្នុងវិស័យផ្សេងៗដូចជា ខ្សែចុច គ្រឿងអគ្គិសនី យានយន្តថាមពលថ្មី 5G និងវិស័យផ្សេងៗទៀត។

2. សំ: តើយើងអាចធ្វើយ៉ាងដូចម្តេចដើម្បីធានាថាសុទ្ធភាពរបស់ខ្យល់ដែលធ្វើពីថ្មីអាចត្រូវបានរក្សាទុក?

A: យើងតាមដានបែបបទរបស់ការធ្វើដំណើរការជាពេលពិតតាមប្រព័ន្ធសម្បូរសម្បទា ហើយមានចំនួនអត្ថបទសិទ្ធិបណ្តឹងជាតិនិងសិទ្ធិបណ្តឹងប្រើប្រាស់។ ឧទាហរណ៍ ខ្សែដែលបានថតផ្ទៃពហុកោះសម្រាប់សាកល្បង 5G ដែលដោះស្រាយបញ្ហាអំពីការភ័យខ្លាច ហើយមានភាគរយផ្សាយនៅក្នុងប្រទេសចិនចំនួន 11.2%។

3. Q: តើស៊ីលីដែលប្រើសំរាប់ផ្ទៃគ្រប់គ្រងត្រូវបានបំបែកដោយស្តង់ដារខ្ពស់ឬទេ

A: យើងប្រើខ្សែ锏ដែលត្រូវបានធ្វើសម្រាប់ការសម្រេចអុកស៊ីសែនទាបនិងគ្មានអុកស៊ីសែន ដែលល្អជាងខ្សែ锏ទូទៅនៅក្នុងការឆ្លើយតបអំពីការអុកស៊ីសែននិងការបញ្ចូលបច្ចេកទេស ហើយបានឆ្លើយតបការស្គាល់នៃឧស្សាហកម្ម។ ឧទាហរណ៍ សារភាពស្ទើរស្ទាប់នៃស៊ីលីគឺ 99.97% ដែលធានាថាគ្មានអេឡិចត្រីស៊ីតាប់ខ្ពស់និងការបង្កើតស្ទើរស្ទាប់តាមរយៈការប្រើប្រាស់យ៉ាងរយៈពេលវែង។

4. Q: តើពេលវេលាដែលត្រូវសម្រេចសម្រាប់ការដឹកជញ្ជូនបញ្ជីមានប៉ុន្មាន?

A: សម្រាប់ស្តុក យើងអាចដឹកទំនិញទៅចំណុចដំណើរការដែលបានកំណត់ក្នុង 7 ថ្ងៃសប្តាហ៍បន្ទាប់ពីយើងទទួលបានកាស៊ី។ សម្រាប់ការផ្ទុក វាប្រើពេលប្រហែល 15 ថ្ងៃដល់ 30 ថ្ងៃដើម្បីដឹកទំនិញទៅចំណុចដំណើរការបន្ទាប់ពីយើងទទួលបានកាស៊ី។

5. សំ: តើយើងនឹងដោះស្រាយបញ្ហាពិនិត្យរបៀបណា

ចម: សូមរក្សាបទពិសោធន៍ផលិតផលជាមួយហើយទៅទាក់ទងនឹងសេវាកម្មអតិថិជន។

6. សំ: តើហេតុអ្វីខ្ញុំទិញខ្ទឹមសម្រាប់ធ្វើតេស្តសាលាអ័ក្សីមានចំណុចបែបនេះច្រើននៅក្នុងតេស្ត

A: ស្តង់ដារជាតិបានកំណត់ថា វិធីសាស្ត្រត្រឹមត្រូវសម្រាប់ការយកគំរូមកធ្វើតេស្តគឺ គំរូមិនគួរត្រូវបានគេទាញ ឬបត់បែនដោយគ្មានហេតុផលនៅពេលដកវាចេញពីកញ្ចប់។ មុនពេលធ្វើតេស្តនីមួយៗ គួរដកខ្សែថ្នាំកូតចេញឲ្យបានគ្រប់គ្រាន់ ដើម្បីធានាថាគំរូនោះមិនមានខ្សែដែលខូចខាតនៅខាងក្នុងនោះទេ។

7. សំ: តើហេតុអ្វីបានធ្វើតេស្តអ៊ីមពេแดนៃត្រូវបានធ្វើឡើងខ្ពស់ជាងចំណុចបញ្ជាក់

A: มาตรฐานแห่งชาติกำหนดสภาพแวดล้อมการทดสอบความต้านทานที่ 20 ℃ ในภูมิภาคตอนใต้ เวลาทดสอบพื้นฐานมักเกินกว่า 30 ℃ ในสภาพอากาศร้อน และลูกค้าทั่วไปไม่มีห้องปฏิบัติการอุณหภูมิคงที่ดังนั้นผลการทดสอบจึงจะสูงขึ้น หรือสามารถแปลงตามดัชนีอุณหภูมิเป็นความต้านทานที่ 20 ℃ ได้

8. คำถาม: เหตุใดถึงมีความแตกต่างของสีระหว่างสองชุดสินค้า

คำตอบ: สายไฟเคลือบ enamel มุ่งเน้นประสิทธิภาพของสินค้าเป็นหลัก ความแตกต่างเล็กน้อยของสีไม่ส่งผลกระทบต่อคุณภาพ โปรดใช้งานได้อย่างสบายใจ

9. คำถาม: ในระหว่างการใช้เส้นลวดบาง จะมีลวดหลายเส้นและไม่สามารถหาลวดเหล่านั้นเจอ

ក: កម្លាៅងដែលអន្តរាល់សរសៃដែកតូចមានកម្លាៅងទាញខ្សែទន្រ្ទានទាប ហើយងាយបែកខ្សែ។ គ្រាន់ត្រូវចាប់ខ្សែទាំងអស់ដោយដៃ (អាចមិនចាំបាច់រកខ្សែនៅផ្ទៃខាងលើដែលបានទាញចេញមួយចំនួន) ផ្ទៃខាងលើនៃខ្សែចាស់នឹងប្រមូលយឺតយ៉ាវ ដកយកខ្សែចាស់មួយចំនួនចេញ ហើយចុងក្រោយនឹងក្លាយជាខ្សែមួយ។ ការរកខ្សែគឺដើម្បីដកយកខ្សែចាស់មួយចំនួន សូមអស់ពីការព្រួយបារម្ភ ហើយប្រមូលដោយការហ៊ាន។