Huaerda Өндірушісінің Сатылымы, 155-ші класс, 0,670 мм Қатты мыс, Полиэфирлы эмальдалған сым, 4800 В, Жоғары пайдалану баламасының қуаты, Электрлы

Сипаттама

Негізгі сипаттамалар

| Өзгеше Материал | Күміс | Дiamетр | 0,670 мм |

| Изоляция материалы | Полиэфирлік бояу | Номиналды кернеу | 4800 В |

| Жоғары жері | Цзянси, Қытай | Модель нөмірі | PEWF |

| Бренд атауы | ХУАЭРДА | Қолдану | Орта және кіші мөлшердегі қозғалтқыштар, жиілікті реттеу |

| Ток өткізгіш түрі | Тығыз | Пішін | Дөңгелек |

| Температура | 155℃ | ТҮР | Изоляцияланған |

Қаптама және жеткізу

| Сатылық бірліктер | килограмм |

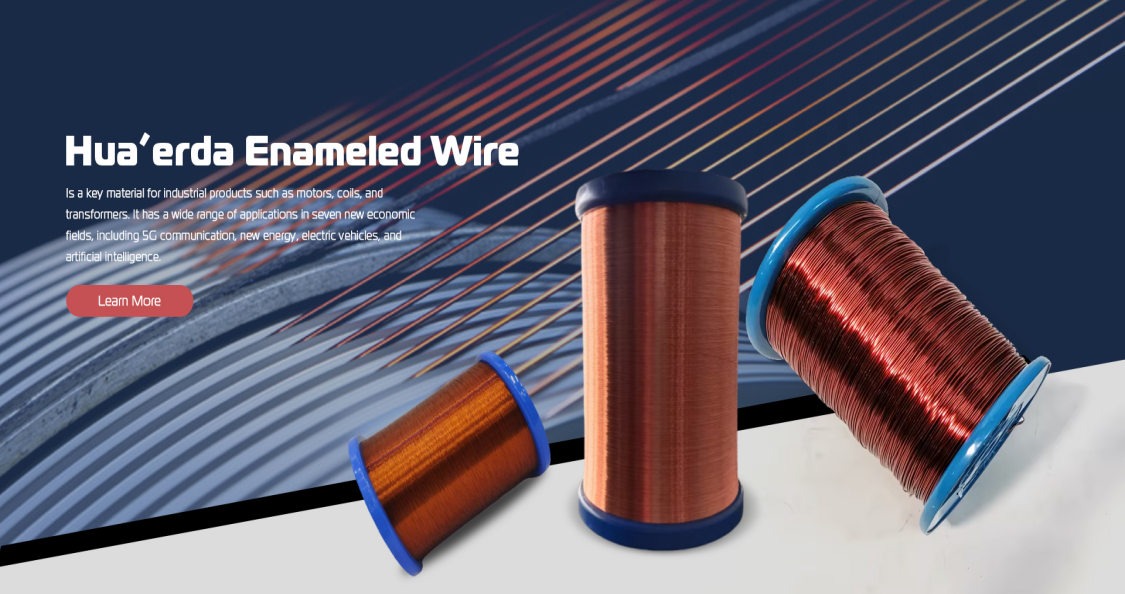

HUAERDA Өндірушісі Сатылым Классы 155 0,670 мм Қатты Мыс Полиэфир Эмалды Сым — сенімді және тиімді электр энергиясын беруге арналған жоғары сапалы электр сымы. Бұл өнім қатты мыстан жасалған, бұл өте жақсы электр өткізгіштікті және беріктікті қамтамасыз етеді. 0,670 мм қалыңдығы бар бұл сым жоғары кернеуді ұстай алатындай берік болып келеді, сондықтан электрлік қолданыстардың әртүрлі түрлері үшін қолайлы.

Бұл сым полиэфир эмалімен жабылған, бұл оны жылуға, ылғалдылыққа және үйкеліске қарсы берік қорғайды. Класс 155-ке арналған изоляциялық бағалау сымның 155°C дейінгі температурада қауіпсіз жұмыс істеуіне мүмкіндік береді, сондықтан ол жұмыс істеу кезінде жылу бөлетін қуатты адаптерлер, трансформаторлар, электр қозғалтқыштар және басқа электр құрылғылары үшін идеалды таңдау болып табылады. Полиэфир эмалінің жабылуы қосымша шамалы ток жүретін сызықтар мен электр істен шығуларын болдырмауға көмектеседі, себебі ол өте жақсы изоляциялық қасиеттерге ие.

HUAERDA эмалді сымының негізгі ерекшеліктерінің бірі — 4800 В дейінгі жоғары кернеуді шыдай алуы. Бұл оны қуатты адаптерлер мен сенімді электр энергиясын жеткізу маңызды болып табылатын басқа электр жабдықтары үшін үлкен таңдау етеді. Сымның жоғары кернеуге төзімділігі қауіпсіз жұмыс істеуді қамтамасыз етеді және компоненттердің электр бұзылуы немесе зақымдану қаупін азайтады.

HUAERDA сенімді электр өнімдерін шығарумен танымал, бұл эмальдалған сым да басқа емес. Оның қатты мыс негізі электр кедергісін төмендетеді, бұл қуат адаптерлерінің тиімділігін арттырып, энергия жоғалтуын азайтады. Бұл осы сымды қолданатын құрылғылардың суық және тиімді жұмыс істеуіне мүмкіндік береді, олардың қызмет ету мерзімі мен өнімділігін ұзартады.

Бұл қатты мыстан жасалған полиэфир эмальдалған сым өндіріс немесе жөндеу процестері кезінде жұмыс істеуге оңай. Оның тегіс изоляциялық қабығы орамдау мен жұмыс істеуді жеңілдетеді, сондықтан электриктер мен өндірушілер үшін бұл таңдауға лайық. Жаңа электр құрылғыларын жинау немесе бұрынғыларын жөндеу болсын, HUAERDA эмальдалған сым сенімді өнімділікті ұсынады.

HUAERDA Өндірушісінің Сатылым санаты 155 0,670 мм Қатты мыс полиэфир эмальді сым жоғары кернеу мен жоғары температураға шыдамды электр қолданбалары үшін құрылған төзімді, жоғары өнімді сым. Оның қатты мыс негізі, жоғары изоляциялық бағасы және өте жақсы кернеуге шыдамдылығы оны қуат адаптерлері мен басқа электр жабдықтары үшін идеалды таңдауға айналдырады. Электр сымдарына қойылатын сапа мен тиімділік үшін HUAERDA-ға сеніңіз

ТҮР |

Полиэстер |

Модификацияланған полиэфир |

Полиизолятор |

Полиизолятор |

Полиэфиримид |

Полиамид-имид |

Код |

PEW, QZ |

PEW, QZ |

UEW, QA |

UEW, QA |

EIW, QZY |

EI/ALW, Q-ZY/XY |

Жылу класы |

Класс B, 130℃ |

Класс F, 155℃ |

Класс F, 155℃ |

Класс H, 180℃ |

Класс H, 180℃ |

Класс H, 200℃/ 220℃ |

1. С: Эмал сымның ең аз диаметрі қаншалықты жіңішке болуы мүмкін

Ж: Біз жасайтын эмаль сымның ең кіші диаметрі 0,060 мм дейін жетеді. Біз жоғары дәлдікті талап ететін жағдайда да үздік изоляция мен ыстыққа төзімділікті сақтау үшін ақылды процессті басқару технологиясын қолданамыз, ол кеңінен кликтер, электр құрылғылары, жаңа энергетикалық көлік, 5G байланысы және басқа да салаларда қолданылады.

2. С: Эмаль сымның сапасын тұрақты ұстау үшін қалай әрекет ету керек

Ж: Біз ақылды өндірістік жүйе арқылы процесстік параметрлерді нақты уақытта бақылаймыз және бірнеше ұлттық деңгейдегі ойлап табыстар мен пайдалану моделіне ие патентті технологияларға ие болдық. Мысалы, 5G байланысы үшін көп қабатты композитті эмаль сым қаптаманың жабысу проблемасын шешеді және оның ішкі нарықтағы үлесі 11,2% -дан асады.

3. С: Өткізгіш материалдар жоғары стандарттарға сәйкес келеді ме

Ж: Біз отырықтырылған төменгі оттегі және оттегісіз мыс сымдарды пайдаланамыз, олар тотығуға тұрақтылығы мен өткізгіштігі жағынан қарапайым мыстан жоғары, сондай-ақ өнеркәсіптік сертификаттан өтті. Мысалы, өткізгіштің тазалығы 99,97%, бұл кедергінің төмендігін және ұзақ уақыт пайдалану кезінде жылу бөлінудің аздығын қамтамасыз етеді.

4. С: Тапсырысты жеткізу үшін әкелу мерзімі қаншалықты

Ж: Барлық тауарлар бар болса, депозит алғаннан кейін 7 жұмыс күні ішінде жүк жіберу портына жеткіземіз. Өндіріс мерзімі бойынша депозит алғаннан кейін жүкті жіберу портына жеткізу үшін әдетте 15-30 күн қажет.

5. С: Сапа мәселелерімен қалай күресу керек

Ж: Өнім үлгілерін сақтап тұрыңыз және қызмет көрсету бөлімімен байланысыңыз.

6. С: Неліктен тұзды су сынағында көп санды тесіктері бар эмаль сым сатып алу керек

Ж: Ұлттық стандартқа сәйкес, сынақ үшін үлгі алу дұрыс әдісі – оны қораптан шығарған кезде үлгі керілуге немесе қосымша иілуге ұшырамауы тиіс. Әрбір сынақтан бұрын үлгіде зақымданған сымдар болмауы үшін жеткілікті эмалды сым шығарып тасталуы тиіс.

7. С: Неліктен кедергінің сынағы көрсетілген аралықтан жоғары болып шықты

Ж: Ұлттық стандарт 20 ℃ температурада кедергіні сынау ортасын көздейді. Оңтүстік аймақтарда негізгі сынақ уақытында 30 ℃ астам ыстық ауа райы болады және жалпы клиенттердің өзінде тұрақты температура зертханасы болмайды, сондықтан сынақ нәтижелері жоғары болуы мүмкін. Немесе температураны 20 ℃-қа дейін түрлендіріп есептелген кедергіге сәйкес келеді.

8. С: Неліктен өнімнің екі партиясында түрлі-түрлі түр айырмашылығы бар

Ж: Эмалды сымның негізгі мақсаты – өнімнің қасиетіне қол жеткізу. Түрлі-түстің кішігірім айырмашылығы сапаға әсер етпейді, өнімді пайдалануға сенімді болыңыз.

9. С: Жіңішке сымды пайдалану кезінде көптеген жіптер болады және жіптерді табу мүмкін емес

A: Жіңішке жіптің созылу күші салыстырмалы төмен, жіп оңай үзіледі. Жіптің барлығын қолмен біріктіру керек (жіптің бетінен жіптің бір бөлігін тартып алуға болмайтынын табу), қалдық жолдың беті баяу жиналады, кейбір қалдық жолды алып тастау керек, және соңында жіп болып қалады. Жіпті табу қалдық жолдың кейбір бөлігін алып тастау, сондықтан қорқынышсыз беткені жинауға болады