Huaerda PEW Model Class 130 1.740mm 5000V Polyester Paint Enameled Copper Wire for Power Tool Motors & Shock Resistance

Mkpakọsi

Ihe ndị bụ isi

| Mkpụrụ Obere | Bare Copper | Diameter | 1.740mm |

| Mkpụrụ Ngwakọta | Polyester paint | Nkwerẹ mmepụta | 5000V |

| Ebe Mmalite | Jiangxi, China | Nọmba nlereanya | PEW |

| Aha ika | HUAERDA | Ngwa | Ihe mmetụta ọnụ ọgụgụ na eme, micro |

| Conductor Type | NKE NKE | Nha | Oke |

| Temperature | 130℃ | Ụdị | Insulated |

Nkwakọ ngwaahịa na nnyefe

| Selling Units | kilogram |

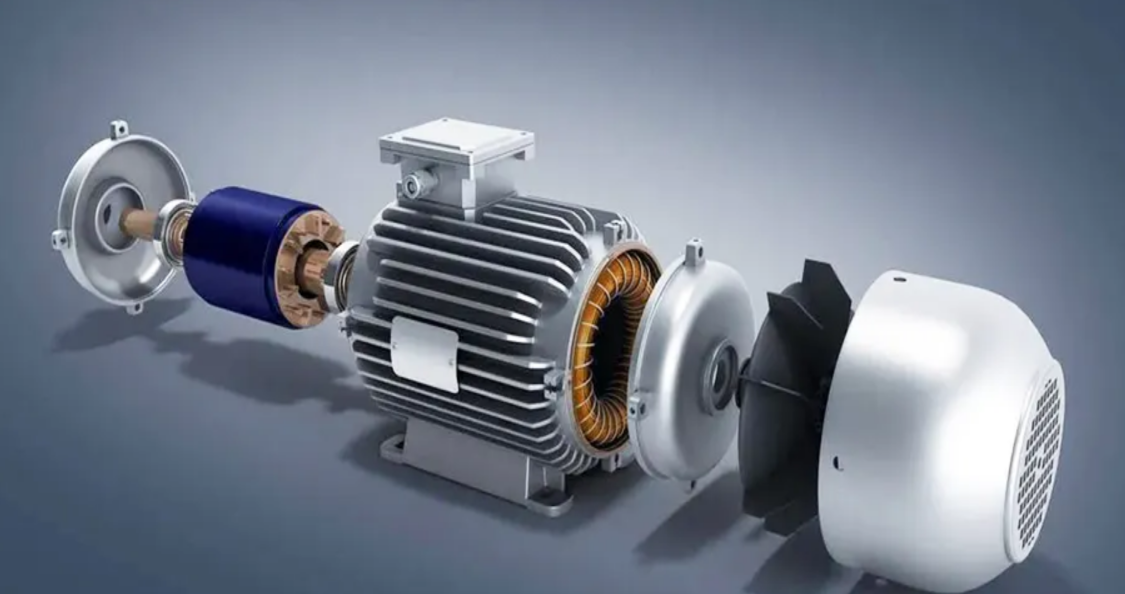

Akpa akwụkwọ enameled HUAERDA PEW Model Class 130 1.740mm Polyester Paint Enameled Copper Wire bụ akpa akụkọ dị ịrịrí e were ya mee ihe na emechaa ya maka ngwaọrụ ike na ihe ọzọ elekereekere nke chọrọ ịdị ụtọ na ịdị irè. Akpa akụkọ kopọ nwee akwụkwọ polyester dị mkpa nke mere ya kwụsị n'ime ọcha, egwu, na ihe ọzọ ndị pụtara ya, nke mere ya bụ isi ozi maka obere obodo ndị chọrọ.

Otu n'ime ihe ndị dị mkpa nke akpa akụkọ a bụ ọrụ insulation class 130 ya, nke pụtara ọ nwere ike imepụta ọcha ruo 130 degrees Celsius gaa n'ihu ịgbanwe. Nke a mere ya kacha mma maka akpa akụkọ na ngwaọrụ ndị ga-egbu ọcha mgbe ọ na-arụsi ike. Oke 1.740mm nke akpa akụkọ nwere ike ikuku ike na ịdị irè, nke mere ka ike gaa n'ihu mgbe akpa akụkọ teterepụtara na ọ dị irè.

Nchịkọta enamel polyester na-ekpuchi ike maka ịgba na ike ịgba nke wire. Nke a dị mkpa n'ụzọ ezigbo, ebe ihe dị ọgwụgwụ nwere ike ịdị ọgwụgwụ na ịgba. Nchịkọta a na karịsịa ike copper wire maka ịdị nke ọma na ihe ọmụmụ mmadụ, na-arịọ ịdị nke ọma na-enyere aka ịgbachi oge nke wire.

HUAERDA dị ka onye na-ewe ike na ike ezigbo ihe elekere, ma nke a PEW Model Class 130 copper wire na-abụkarị ike a. Wire a na-edepụta maka ịdị mma nke onye ọrụ, onye nnwale, na onye na-eme ihe na-eji ya maka winding motors, coils, transformers, na ihe elekere ndị ọzọ.

Akụkụ enameled copper a na-enye nkume eletrik dị mma na akara ike eletrik nke copper. O dị mfe ịtụkwasị obere n'ihi akụkụ dị mfe ya, nke na-enye ohere maka ikpuchi zuru oke na mpempe mgbe ị na-arụ ọrụ ma ọ bụ mara motors na ọrụ ndị ọzọ. Nke a na-egosi na njikọ eletrik dị mma na efu efu.

HUAERDA PEW Model Class 130 Polyester Paint Enameled Copper Wire bụ akụkụ dị elu, na-enwe nkume ọcha na-enweghị nkume, dị mma maka ihe ngụnụ ike motors na njikọ ndị ọzọ. Ọ bụrụ na ị na-marachite motor ma ọ bụ na-arụ ọrụ ihe ngụnụ eletrik ọhụrụ, akụkụ a na-enye nsogbu karịrị na nghọta dị ogologo. Akụkụ polyester dị mma na akụkụ copper ya na-eme ka ọ bụrụ nhọrọ oma maka onye ọ bụla ga achọ akụkụ enameled copper dị elu na dị mma

NKECHI:

Ụdị |

Polyester |

Modified Polyester |

Polyurethane |

Polyurethane |

Polyesterimide |

Polyamide-imide |

Code |

PEW, QZ |

PEW, QZ |

UEW, QA |

UEW, QA |

EIW, QZY |

EI/AIW, Q - ZY/XY |

Ọkara Iru Ebe |

Ọkara B, 130℃ |

Ọkara F, 155℃ |

Ọkara F, 155℃ |

Ọkara H, 180℃ |

Ọkara H, 180℃ |

Ụdị H, 200℃/220℃ |

Hua'erda Wire & Cable Group Co., Ltd. bụ onye na-eme ihe enameled wire, onye isi na-agba electromagnetic wire industry na China, kama otu n'ime asaa 500 dị na Zhejiang Province

Nnụnụsiị na-ekwe omume maka ịgwụ ụlọ ọgwụ na ụlọ ọgwụ dị mma, njikọrị dị ụtụ na njikọrị dị mma. Nnụnụsiị na-ekwe omume dị ka “Nnụnụsiị dị elu nke na-achịkwa ụmụnna dị elu”, “Ụlọ ọgwụ dị mma dị elu nke na-achịkwa ụmụnna dị elu”, “Nnụnụsiị dị elu nke na-achịkwa ụmụnna dị elu dị ka ụlọ ọgwụ dị mma, dị mma, dị mma na ụlọ ọgwụ dị mma”, “Onye nleta dị elu nke na-achịkwa ụmụnna dị elu”, “Onye nleta dị elu nke na-achịkwa ụmụnna dị elu”, “Onye nleta dị elu nke na-achịkwa ụmụnna dị elu” na “Onye nleta dị elu nke na-achịkwa ụmụnna dị elu”. Onye nleta dị elu”, “Top Ten National Electromagnetic Wire Processing Enterprises”, “Nke mbụ nke 5G+Internet Demonstration Enterprises na Jiangxi”, “Nke mbụ nke Small Lighthouse Enterprises maka Ịgbazọ Ntụle na Jiangxi” na ihe dị ọcha ọzọ. “na ihe dị ọcha ọzọ

Hua'erda enameled wire, nke dị mma ma ọ bụghị mma, nwere omenala dị elu na agwa dị elu, nwere mma na mpaghara dị elu na Zhejiang, Fujian, Guangdong, Shanghai kuma mpaghara Southeast Asian

1. Q: Ọ dị mma ka ụkara kacha ntakịrị nke enameled wire dị mma

A: Nke dị ọnụ ọnụ mmiri wire dị mma anyị kwado pụtara dị ka 0.060 mm. Anyị na-eji sistemụ na-akpali ike iji jikọta na mma na mma nke mma nwere ike ime mgbe ị chọrọ ike dị mma, e nwere ike ime na ụlọ dị iche iche, egwuregwu, agụmakwụcha, 5G na mmemme na ndị ọzọ.

2. Q: Kedu iji chekwaa na mma nke enameled wire dị mma

A: Anyị na-eji sistemụ maka ịgbakọ maka ịgbakọ enye paramita nke ọma n'otu oge ahụ, na nkebi nke patentị nkeji na teknụzụ nke ụlọ. Dịka ọnụ ọgụgụ, enameled wire nke ọma maka 5G communication mere mmecha nke ịgbakọ na-eme ka o pụta na-enye ụlọ dị elu 11.2% n'ime ụlọ dị mma.

3. Q: Dị ma ụlọ dị mma nke conductor emere ụzọ dị mma

A: Anyị na-eme iwu nke dị mma nke copper wires na-annealed na copper wires dịghị oghere, nke dị mma karịa copper ordinary dị ka oxidation resistance na conductivity, kama na-abụrụ na ọ dị mma. Dịka ọ na-eme, ịdị mma nke conductor bụ 99.97%, nke mepụtaghị ya ike na-eme n'ụtọ n'ime ọrụ dị ukwuu.

4. Q: Ọnwa ole bụ lead time maka ịgbapụta order

A: Maka stock, dị ka izughi anyị nwere ike inwepụta ihe na port nke loading within 7 working days mgbe anyị rụọrụ deposit. Maka ọrụ, ọ dị mma karịa 15 days na 30 days maka inwepụta ihe na port nke loading mgbe anyị rụọrụ deposit.

5. Q: Kedu iji deal with quality problems

A Biko epughị ya product samples na-en contact customer service.

6. Q: Kedu ihe m na-ebute enameled wire nke dị mma karịa dịghị iwu dị na salt water test

A: Usosiri nke dị na nchịkwa na ụzọ dị mkpa maka ịgba sample maka test bụ na ngwaọrụ ahụ emechara ike ma ọ bụ ike na-enweghị ike mgbe ọ dị na mpako. Mgbe ọ bụla gara aga nke test, enwere ike ịgba enameled wire dị mkpa maka enweghị ngwaọrụ ahụ nke enwere ike ọ dịghị mkpa.

7. Q: Kedu ihe mere resistance test dị elu karịa ihe nke a kpebisiri

A: Otù àjánie nke àjánie nke ọ dị mma maka ọmịna ọmịna nke 20 ℃, nke dị na mpaghara nkeji bụ isi test bụ elu karịa 30 ℃ karịa karịa, ma ọ bụghị onye nwere laboratory nke mma mma, maka ọmịna ga-abụ elu. Ma ọ bụ dị ka ihe nleba ahụ dị na ọmịna nke ọ dị na 20 ℃.

8. Q: Kedu ihe mere ebe dị iche nke ahịrị nke abụọ

A: Enamel wire bụ isi ihe mere ihe nke ọ dị mma, ahịrị dị mfe emeghị mma, biko tinye onwe gị na ịmụ.

9. Q: Mgbe ị na-ahụrụ iho zuru oke, nwere ike ime nụnụ dị ọnụ ma enweghị ike ime nụnụ

A: Ike nke nchekwa akpụkpọ dị mfe, ọ dị mkpa ike ka akpụkpọ pụọ. Mere ka ịnye akpụkpọ niile (ị nwere ike ekwe nkwa akpụkpọ dị na agụụ akpụkpọ site na ịkpụ ụzọ), agụụ akpụkpọ na-agbanwe n'ime, pụọ akpụkpọ dị na agụụ, na nke keresụ ga-abụ akpụkpọ. Ikwubere akpụkpọ bụ ime ka ị pụọ akpụkpọ dị na agụụ, kwalite ka ị na-agbanwe ya n'ime.