The difference between copper and aluminum core enameled wire knowledge:

Enameled wires are indeed key elements in certain electrical work; these are the materials that carry the current from one place to another. Copper core enameled wires and aluminium core enameled wires are two of the most popular types of enameled wires used in the aforementioned applications. Although they both fulfill the same functions there are noticeable differences between the two and certain considerations need to be taken into account when selecting the most suitable type for a particular electrical job.

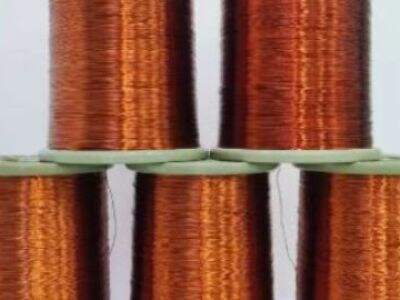

The enameled wires are manufactured of copper, which is a very effective conductor of electricity and makes it easier for the current to pass through with less resistance. Copper Core Round 50 Meters Enameled Wire Copper Winding Coil Magnet Wire 0.3-1.6 mmDescricption :Copper Enameled Round Wire is the most widely used wire for general applications where the operating temperature does not exceed 155¡æ.ustomed to hold/hang items to brighten up those special day, great for outdoor and indoor decoration.Package includeds :1 x More than 50 meters Round 50 Meters Enameled WireDetails pictures : Copper core round 50 meters enameled wire copper winding coil magnet wire 0.3-1.6 mmFileChooserUpload a file, select a file for upload you must upload from your post on a postcomment, and show the uploaded somewhere in that post.Attachments. Whereas, the aluminum core enameled wire is again formed by using aluminum which has lower conductance as compared to copper. Therefore, aluminum core enameled wire can not be more conductive than copper core enameled wire.

Comparison of electrical efficiency between copper and aluminum core enameled wire:

As for the electrical performance, copper enameled wire is far better/more efficient than the aluminum enameled wire. Copper has better electricity performance than aluminum, so copper core enameled wire has higher carrying capacity than aluminum core enameled wire. This makes the copper core Enameled Wires more efficient in transmitting electricity than other wires over long distances.

In contrast, polyurethane aluminum wire tends to be used only when its cost is a primary issue, as it is not as easy to work with nor does it hold up as well as 16-gauge wire of other varieties. 2), Aluminum is cheaper than copper, this is why aluminum enameled wires is a more budget-friendly choice than copper ones for many application. But it is also important to bear the possible energy loss and kind of constraint for using aluminum core enameled wire in electric field.

Factors to consider to make copper core enameled wires on inductor winding improve the efficiency:

High Electric Conductivity and red copper core enameled wire is used with Allwin advanced tech on this machine to gurantee high electric efficiency and stable performance. A thin layer of enamel insulator is wrapped around the copper core, then wrapped around with a continuous transposed in a concentric layer. This insulation also serves to keep up the wire's electrical conductivity and forestall vitality leaks throughout electrical transmission.

Also, copper core enameled wires are usually formulated with particular features to improve their suitability in various applications. For instance, heatproof copper core enameled wire is available in high temperature. Others will perhaps have increased flexibility to fit into small spaces. These technological improvements add to the general efficiency and dependability of copper core enameled wires available for a variety of electrical purposes.

Study of advantages and disadvantages of aluminum conductor enameled wire in electrical equipments:

Although copper-core enameled wire is widely used in electrical field for its high electric efficiency, aluminum-core enameled wire still has its own advantages and disadvantages. One of the key benefits of aluminum core Enameled Wires is that they are more economical for a given current-carrying capacity than copper core Enameled Wires. This could be an important consideration in budget constrained applications.

However, the aluminum core enameled wire has a poor conductivity and the conductive capacity can be inferior to the copper core enameled wire, so as to bring about larger energy loss and lower efficiency in some of the applications. Also, the wires with an aluminum core enamelling are more prone to oxidation and mechanical damage which can compromise long-term reliability and performance.

How to select suitable enamelled wire to ensure best electrical conductivity for various usage:

When choosing the optimal type of enameled wire for a given electrical application, it is fundamental to take into account the needs of the application as well as the necessary level of electrical efficiency. Generally, copper core enameled wire is recommended its applications that demands high conductivity and low energy loss and good performance. This may comprise power line, electric motor, transformer and other h igh power applications.

Alternatively, aluminum core enameled wires may work well for an application where cost is a major concern and where the electrical efficiency requirements are somewhat less demanding. Such as household appliances, lamps, etc. all can be used in the low-frequency range, which also can be used A aluminum enameled wire lost due acceptable.

In summary, Enameled Wire each have their own advantages and disadvantages, and which is employed is determined by the requirements of the electrical application. HUAERDA provides various enameled copper wires, enameled aluminum wires for different purpose according to customers’ requirement. By learning how these types of wires differ and their electrical efficiency, knowing which enameled wire to select becomes a straightforward process for your specific application.

Table of Contents

- The difference between copper and aluminum core enameled wire knowledge:

- Comparison of electrical efficiency between copper and aluminum core enameled wire:

- Factors to consider to make copper core enameled wires on inductor winding improve the efficiency:

- Study of advantages and disadvantages of aluminum conductor enameled wire in electrical equipments:

- How to select suitable enamelled wire to ensure best electrical conductivity for various usage: