When it comes to electrical uses the quality of the annealed bare copper is definitely important this kind of wire is widely use for its good conductive performance and malleability tensile strength and elongation are two notable technical specifications to take into account those factors dictate how much stress the wire can absorb and how much it can stretch before breaking. We at HUAERDA always check the quality of our anneal Bare Copper Wire in comparison to these requirements which ensures optimum utilization and utmost user satisfaction in all Electrical applications.

The role of tensile in annealed Stranded naked copper wire

Tensile strength is also really important for the type of copper wire she’s talking about it informs you of how strong the wire is when you tug on it if the wire is high-tension you won’t break it easily “So that’s very important for something like power lines or car engines where the wire needs to sustain a lot of pull and weight.” At HUAERDA we ensure our copper wire is strong enough to not snap under pressure this keeps the system going smoothly and safely.

In compliance with the industry standards meeting the industry standard for the length in wire

Another neat thing to think about with copper wire is elongation it’s how far the wire can stretch before it will break think of a rubber band: If it stretches a great deal before breaking it is high in elongation. This is good for electrical wires since they occasionally have to round corners or stretch a little when they are being installed.

A few tips on how you can guarantee the quality and reliability of annealed bare copper wire

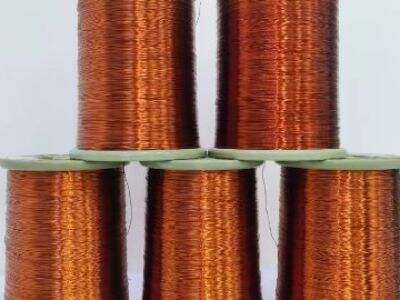

We conduct a lot of tests in making certain our Polyester Enameled Copper Round Wire is the finest. We measure how strong it is and how much it can stretch we also consider how readily it transports electricity this testing like all the testing we do helps ensure that when you use our wire it won’t let you down it’s about the wires being trustworthy and safe, and they do the things that they do.

What is the effect of the technical conditions for electrical conductivity in respect of copper wire

The fact that copper wire can carry electricity is Super Important this is called electrical conductivity when wire has good conductivity electricity flows through it easily this is important for such necessities as keeping your lights on or computer running. We at HUAERDA care much of it and ensure our copper wires are best for the electricity transport safely and effectively.

Performance and durability through the use of high strength and high quality spring ball bearings and high tensile strength spring wires

By concentrating on tensile strength as well as elongation we create wires that are not only strong but also flexible this balance is crucial in order to make wires that last a long time and work really well whatever the job. At HUAERDA we strive to create the very best Polyesterimide Enameled Copper Round Wire - promising to ensure they fulfil the requirements of all of our customers while keeping their electrical applications running just as they should.

Table of Contents

- The role of tensile in annealed Stranded naked copper wire

- In compliance with the industry standards meeting the industry standard for the length in wire

- A few tips on how you can guarantee the quality and reliability of annealed bare copper wire

- What is the effect of the technical conditions for electrical conductivity in respect of copper wire

- Performance and durability through the use of high strength and high quality spring ball bearings and high tensile strength spring wires