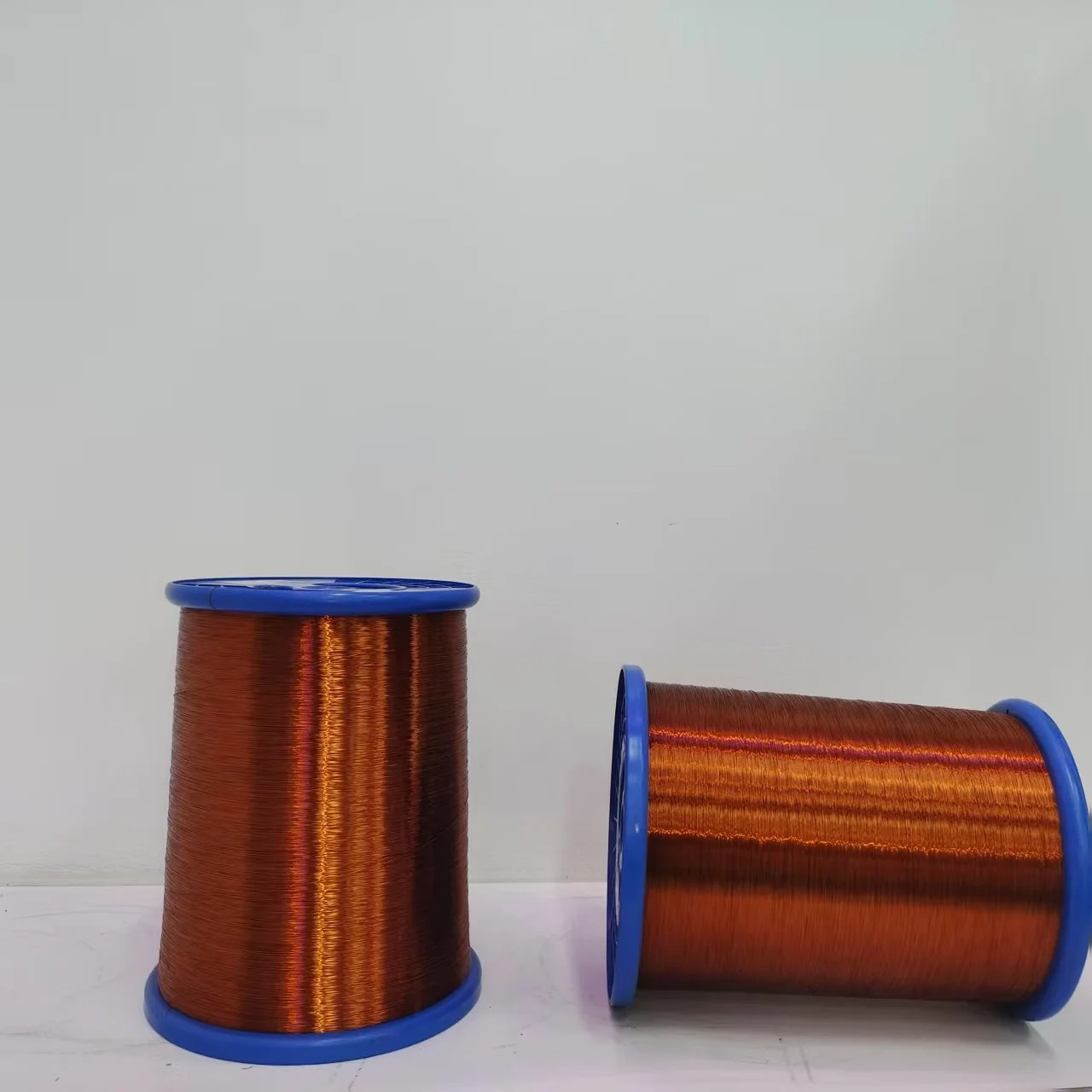

It is important that you select a proper enameled copper wire, especially in industrial winding. The wire is used in many machines and devices. It is very important to make sure the wire will suit your project requirements. A good decision here can make your equipment work better and last longer. HUAERDA knows the value of high grade wire for industrial use. This post will walk you through how to select the best enameled copper wire and where to get good quality products at wholesale prices.

Key Factors to Consider When Choosing Enameled Copper Wire

If you are looking for enameled copper wire used in industrial applications, there are a couple things that you will want to consider. One thing to keep in mind first is gauge of the wire. The gauges tell us the thickness of the wire. Thinner wire might be good for more delicate projects and thicker one for the larger ones. Then try to determine the insulation type. The type of insulation used to guard from heat and damage can vary by the job. Thermoplastic insulation is normal, but thermo-set is more durable for harder service. It’s also a good idea to test the conductivity of the wire. The greater the conductivity, less energy is lost which is very important for its effective performance. Another aspect is temperature ratings. Some more demanding jobs may generate heat, so selecting some wire with high temperature tolerance is good. Lastly, make sure that the wire is flexible enough to suit your requirements and if you plan on wrapping very tightly around cores or spools. Understanding these key factors can help you find the perfect enameled copper wire for your particular application.

Tips for Sourcing High-Quality Enameled Copper Wire Wholesale

Sourcing high-quality enameled copper wire wholesale can be an adventure. To begin with, you should check on reputable suppliers such as HUAERDA online. Websites typically provide detailed product pages, so you can review specifications and see what others have said about the item. And it’s a good idea to visit trade shows or local industry events. Being able to meet suppliers in person and visit the products is what these events offer. You might be able to request samples in advance, so you can quality check your order. And a pro tip if you’re buying in any kind of bulk: Ask about discounts! Most manufacturers such as HUAERDA can offer larger order customers better prices. And social media can offer leads on reliable suppliers and new products. Joining professionals in forums can also be helpful. Also, always focus on the quality of the wire rather than price. A little savings in cost can turn into a big headache later if that wire doesn’t meet your needs. In this way, you will be able to easily and conveniently identify the ideal products available in the market.

Typical Problems In The Sourcing of Enameled Copper Wire for Manufacturing

Many people have encountered common problems in the selection of enameled copper wire for production. First, it’s difficult to find anything in the right diameter of wire, he wrote. Copper enameled wire is available in all sorts of thicknesses, or gauges. Picking the right gauge for your project is crucial. The wire may be too thin; it is easily broken. If it is too thick, it might be heavy and difficult to handle. Just make certain to check the specs you require for your project before this occurs. The wire is also of sub-par quality. Some of the suppliers have very low quality wires available. If the insulation on that wire is bad, it can ruin or short out machines which might cause larger problems later. Never, ever buy without getting samples first or checking the quality beforehand. While the price can also be a problem. Although lower-cost products may be tempting, you will find that they are often lackluster in quality. When you are thinking cost, while it may be true that those like the ones manufactured by HUAERDA may cost more up front, it can also keep money in your pocket in future repairs or replacements. And then there is the added worry about delivery times. The whole manufacturing can be slowed, if the supplier is late to ship. Never forget to Look for The estimated delivery time of the wire and Do Account this around your project! By understanding these problems and by thinking ahead, you can do a better job sourcing enameled copper wire. The thermal rating of any insulation material (including enamels) is always the maximum permissible hottest temperature it is allowed to reach under test conditions including non-stop operation at rated voltage.

What Are The Main Advantages of Using Enameled Copper Wire In Industry?

Excellent conductivity is one of its major benefits. Here’s what that means: Electricity can travel through it easily. As a result, machinery and equipment operate more efficiently with enameled copper wire. Increased efficiency means lower energy costs which is great for any industry. Another benefit is its insulation. The wire is covered with enamel making it shielded from possible shorts. This means that if you are using enamel wire, namely those from HUAERDA, you can guarantee it to last long helping you avoid machine downtime. Durability is another key advantage. Enamel copper wire has excellent thermal property, it can work under a wide range of temperature. If you have wires, particularly in manufacturing settings where there are harsh environments used in these facilities if they get run over by something it can cause that wear, Wellock said. Further, the enameled copper wire is relatively space saving against other kinds of wiring. This is useful in machines that have very little space. Finally, a enameled copper wire can enhance safety of use. Because it has a high short-circuit strength, there is less chance for electric fires or equipment failure. All of these advantages made enameled copper wire a popular option in many industries.

How can You Avoid the Common Mistakes when Buying an Enameled Copper Wire

In enameled copper wire purchase, there are some optimistic errors to avoid. First, don’t buy too quickly. When you are first starting out, it can be tempting to rush to order wire so that you can experiment with your new project but this is a mistake. Spend a bit of time on research about types enameled copper wire there's such variety out there. Be sure to know the type of clamp and size that will work best for your particular use. For instance, if you’re working on a project that demands high heat resistance, then you need to find out the wire that can withstand those conditions. After that, always verify the supplier’s reputation. Not all vendors offer high-quality items. Search reviews of the company and its wires. Huaerda is a reputable manufacturer of copper enameled wire, and it’s best to check out their product offerings. And always ask questions before you purchase. Any query that you have, do not hesitate to ask the suppliers before making a decision. They should be able to tell you what the wire’s rating is, how good the quality is and if it’s suitable for your needs. Another mistake you should avoid would be disregarding the desired length of a wire. Buy too little, and you can wind up needing to order more, holding up your project. Order too much and you can end up squandering money. Lastly, remember to take shipping costs and delivery times into consideration as these can affect your timeline for a project. By taking the time to know what you want to accomplish and plan beforehand, you can circumvent some of the common mistakes that individuals make prior to purchasing enameled copper wire.

Table of Contents

- Key Factors to Consider When Choosing Enameled Copper Wire

- Tips for Sourcing High-Quality Enameled Copper Wire Wholesale

- Typical Problems In The Sourcing of Enameled Copper Wire for Manufacturing

- What Are The Main Advantages of Using Enameled Copper Wire In Industry?

- How can You Avoid the Common Mistakes when Buying an Enameled Copper Wire