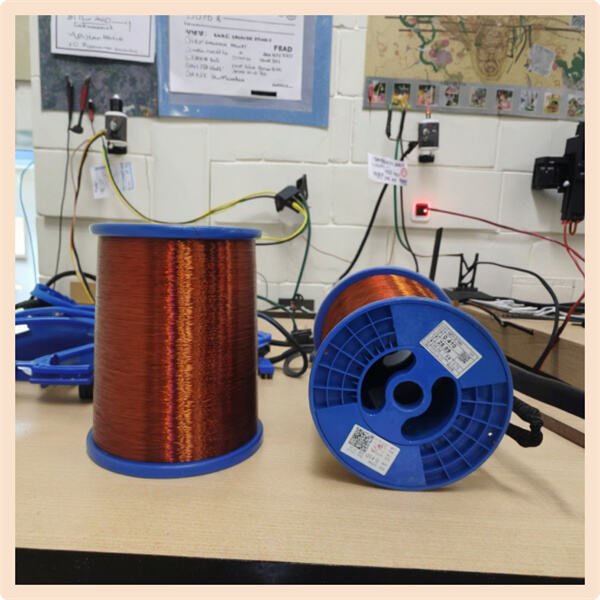

It is a type of wire used in the construction of devices, and may be copper or aluminium; Enamel coated magnet wire is meant to withstand the high temperature demands made by electrical components whose temperatures can cause normal wire to crack. This involves wrapping a thin wire in an enamel that acts like any normal type of paint only it could protect the wire making it work better. Magnet wire is a type of winding wire or enameled wire, coated with a thin layer of enamel (think nail polish) and popularly used to carry electricity in many things like appliances, cars, and computers. It can easily melt in the turbine, its like a black painting on a thin wire. It is very thin, but it is so strong, and can save the wire from being damaged.

Positive aspects of enamel coated magnet wire for electrical devices It is highly durable and able to take a lot of wear. Therefore, the wire will be durable, and they are not likely to break soon. Another advantage is that it can act as an enamel cover to shield the wire from any water or heat. It is then possible for the wire to be much more secure in use and may reduce risk of accidents.

If we talk about enamel coated magnet wire, then insulation has a very crucial role. Insulation – this is a protective material that surrounds the wire/s. If the wires are not properly insulated, then there could be a problem with the wiring and electrical devices may face issues. For instance, you'd better pay attention to whether the enamel coated magnet wire is already enameled or not in case it need for further insulation so that you can use well.

Magnet wire can use many different types of coatings, for example enamel coating. Other coatings tend to be thick and strong, yet lack flexibility and allow objects to bend. Because different applications will require a different type of coating for the wire, so choose wisely. One might be better for high temperatures, while another for protecting the wire from water. As long as you can recognize what kind of enamel coating it is, you can rest easy that the right concertina wire is being used in whatever electrical device your company has fabricated.

In the case of electrical systems, using enamel coated magnet wire can help enhance efficiency and reliability. Firewire has a coating of enamel over the wire which allows it to conduct electricity better and waste less energy to heat. This results in better performing electrical devices that consume less energy. The enamel coating can also help protect the wire from damage, which helps to ensure that the electrical system remains functional. Among the essential items in the manufacture of all electrical devices is coated enamel magnet wire.

Copyright © Hua’erda Cable Group Co., Ltd. All Rights Reserved